Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

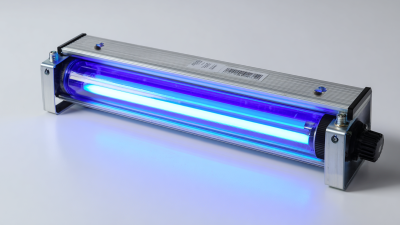

In the rapidly evolving world of industrial processes, the adoption of UV Drying Light technology has emerged as a game-changer. According to a report by Smithers Pira, the global UV curing market is projected to reach $8.5 billion by 2025, driven by the need for faster and more efficient drying solutions across various sectors, including printing, coatings, and adhesives. UV Drying Light not only accelerates curing times but also enhances product quality and reduces energy costs, making it an attractive option for businesses aiming to increase their operational efficiency.

Industry expert Dr. Jane Matthews, a leader in UV technology research, emphasizes the significance of this advancement: “Utilizing UV Drying Light can reduce drying time by up to 70%, allowing manufacturers to improve throughput while minimizing waste.” The benefits extend beyond speed; UV curing is environmentally friendly, as it produces minimal VOC emissions and consumes less energy compared to traditional drying methods. With the growing demand for sustainable practices in manufacturing, UV Drying Light technology stands out as a pivotal solution that aligns with both efficiency and eco-friendliness.

Industry expert Dr. Jane Matthews, a leader in UV technology research, emphasizes the significance of this advancement: “Utilizing UV Drying Light can reduce drying time by up to 70%, allowing manufacturers to improve throughput while minimizing waste.” The benefits extend beyond speed; UV curing is environmentally friendly, as it produces minimal VOC emissions and consumes less energy compared to traditional drying methods. With the growing demand for sustainable practices in manufacturing, UV Drying Light technology stands out as a pivotal solution that aligns with both efficiency and eco-friendliness.

As we delve into the top 10 advantages of using UV Drying Light for efficient curing, it becomes clear that this innovative technology not only meets the needs of today’s fast-paced industries but also paves the way for a more sustainable and economically viable future.

The application of UV light technology for curing processes has transformed industries by significantly reducing drying times. For instance, a wood-shelving manufacturer accomplished an impressive reduction in the drying time for wood panels from two days to just one hour. This enhancement not only boosts production efficiency but also leads to substantial cost savings associated with time and energy usage. The anticipated growth of this technology, projected at 10% per year, underscores the increasing recognition of its benefits across various sectors.

Moreover, the advantages of faster drying times extend beyond industrial applications. In personal care, UV light is becoming increasingly popular for its ability to rapidly cure nail products, providing consumers with salon-quality manicures within minutes. This technology caters to the modern demand for efficiency and convenience, allowing individuals to maintain their beauty routines without the lengthy wait times typically associated with traditional drying methods. The integration of UV light in these diverse applications reflects a broader trend towards embracing innovative solutions that enhance both productivity and user experience.

The use of UV drying light for curing materials presents significant advantages, particularly in terms of enhanced adhesion and bonding strength. When UV light is applied, it initiates a rapid photochemical reaction that effectively transforms liquid adhesives and coatings into solid form. This quick process not only minimizes the time required for curing but also allows for deeper penetration into substrates, leading to a stronger bond. The result is an impressive combination of durability and resilience, as the enhanced adhesion reduces the risk of delamination or failure under stress.

Moreover, the precision offered by UV curing technology ensures consistent and uniform application across various surfaces. This is particularly beneficial when working with complex geometries or challenging materials, where traditional curing methods might fall short. The strong bonds achieved through UV curing can withstand a range of environmental conditions, including moisture and temperature fluctuations, making them ideal for applications in sectors such as automotive, electronics, and construction. Thus, utilizing UV drying light not only boosts efficiency but also significantly improves the performance and longevity of cured products.

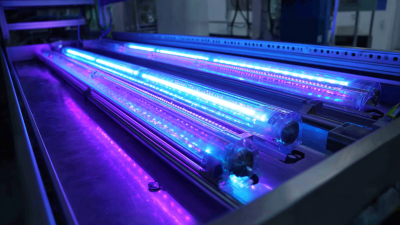

The versatility of UV drying light technology has made it a crucial asset across various industries, particularly in manufacturing, printing, and automotive sectors. According to a report by Smithers Pira, the global UV curing market is expected to grow significantly, reaching approximately $5.4 billion by 2024, reflecting an increasing demand for more efficient and eco-friendly curing methods. The ability to cure inks, coatings, and adhesives rapidly makes UV drying lights an optimal choice for high-speed production processes. For instance, in the printing industry, UV curing allows for immediate handling and finishing of printed materials, significantly reducing turnaround times.

In the automotive sector, UV drying lights are instrumental in ensuring durable coatings and paints are applied effectively. A study by the American Coatings Association highlighted that UV-cured coatings offer better scratch resistance and faster drying times, leading to enhanced productivity on assembly lines. Furthermore, the versatility of UV technology means that it can be adapted for various applications, including wood finishing and electronic component manufacturing, where precision and speed are essential. As industries continue to prioritize efficiency and sustainability, the adoption of UV drying light technology is expected to expand, driving innovations in production techniques across multiple sectors.

| Advantage | Description | Applicable Industries |

|---|---|---|

| Speed | Rapid curing times compared to traditional methods. | Manufacturing, Automotive, Print |

| Energy Efficiency | Lower energy consumption for curing processes. | Packaging, Electronics, Woodwork |

| Improved Adhesion | Greater bonding strength for coatings and adhesives. | Construction, Textile, Machinery |

| Versatility | Can be used on various substrates such as plastic, metal, and wood. | Automotive, Furniture, Graphic Arts |

| Reduced VOC Emissions | Lower volatile organic compounds emissions for safer applications. | Coating, Printing, Food Packaging |

| Consistency | Uniform curing process for reliable quality control. | Electronics, Pharmaceuticals, Cosmetics |

| Flexibility | Can be implemented in various production lines easily. | Automotive, Woodworking, Printing |

| Space Savings | Compact design allows integration in limited spaces. | Manufacturing, Electronics, Laboratories |

| Environmentally Friendly | Minimal impact on the environment due to reduced chemical use. | Textiles, Food Packaging, Cleaning Products |

| Enhanced Durability | Produces harder coatings that resist wear and tear. | Automotive, Industrial Equipment, Furniture |

The use of UV drying light in curing processes brings significant benefits, particularly in terms of environmental sustainability and waste reduction. Traditional curing methods often rely on lengthy drying times and the use of solvent-based products that release harmful VOCs (volatile organic compounds) into the atmosphere. In contrast, UV curing technology dramatically shortens drying times while minimizing emissions, resulting in a cleaner and healthier working environment.

Moreover, UV curing processes are inherently more efficient, as they use less energy and can be integrated into automated systems, leading to lower operational costs. The precision of UV light allows for targeted curing, which reduces the amount of material wasted during production. Additionally, since UV-cured materials often have greater durability and longevity, this further decreases the need for rework or replacement, aligning well with sustainable manufacturing practices. Overall, the improved environmental impact and reduced waste associated with UV drying light technologies represent a significant advancement in the pursuit of efficient curing solutions.

In the competitive landscape of manufacturing, cost-effectiveness is a significant driver of operational success. The integration of UV drying light technology into production processes presents a compelling case for long-term financial benefits. Unlike traditional drying methods that require extended periods and substantial energy usage, UV dryers cure materials almost instantaneously. This leap in efficiency reduces not only cycle times but also labor costs, enabling businesses to increase output without a proportional rise in expenses.

Moreover, the durability and reliability of UV-cured products lead to fewer defects and returns, thereby minimizing additional costs related to rework and waste. This technology often works effectively across various substrates and applications, which can further streamline production lines and reduce the need for multiple drying systems. As companies increasingly turn towards sustainable practices, the energy efficiency of UV drying lights supports a greener operational model, translating to lower utility bills and a reduced carbon footprint. By investing in UV drying technology, businesses can achieve a robust return on investment through enhanced productivity and reduced long-term operating costs.