Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

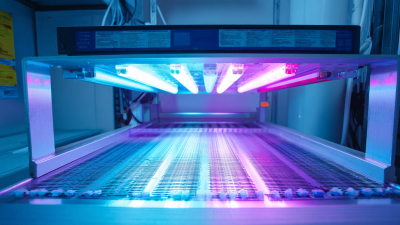

In recent years, the manufacturing sector has witnessed significant advancements driven by technological innovations, particularly in curing processes. One of the standout developments is the adoption of UV LED curing equipment, which has revolutionized industries ranging from printing to automotive. According to a recent market research report by Fortune Business Insights, the global UV curing equipment market is projected to reach USD 3.14 billion by 2026, growing at a CAGR of 12.5% from 2019. This remarkable growth is largely attributed to the enhanced efficiency and cost-effectiveness offered by UV LED technology, which reduces energy consumption, minimizes waste, and accelerates production times. As manufacturers increasingly recognize the potential of UV LED curing equipment, the transition towards more sustainable and innovative practices is not only becoming imperative but is also setting new standards in quality and performance across various applications.

The adoption of UV LED curing equipment in modern manufacturing has significantly transformed product quality across various industries. By utilizing UV LED technology, manufacturers can achieve faster curing times and enhanced adhesion properties, which ultimately leads to higher durability of finished products. According to a report by Smithers Pira, UV LED curing technology has grown at an annual rate of 15%, reflecting the industry’s recognition of its impact on efficiency and product characteristics.

The benefits of UV LED curing extend beyond speed; they also contribute to superior surface finish and reduced defects. Studies have shown that products cured with UV LED emit lower levels of VOCs (volatile organic compounds), making them environmentally friendly, an essential consideration today. For instance, the UV/Vis curing process is reported to reduce curing emissions by over 90% compared to traditional methods, according to the European Coatings Journal. This improvement not only satisfies regulatory requirements but also enhances customer satisfaction, as consumers increasingly favor products that are made with sustainable practices.

Moreover, UV LED curing equipment offers exceptional versatility, allowing manufacturers to adapt to varying material types and applications. The ability to cure a wide range of substrates, including plastics, glass, and metals, has made it a preferred choice across sectors such as automotive, aerospace, and electronics. With the global market for UV curing projected to reach $4 billion by 2025, manufacturers who invest in UV LED technology stand to gain a competitive edge while ensuring their products meet the highest standards of quality.

The integration of UV LED curing equipment in modern manufacturing presents significant energy efficiency advantages, ultimately reducing operational costs. Traditionally, UV curing systems have relied on mercury lamps, which consume considerable energy and require substantial cooling to mitigate heat. In contrast, UV LED technology operates at lower temperatures and consumes up to 80% less energy, facilitating considerable savings in electricity expenses. According to a recent techno-economic evaluation, companies that adopt UV LED systems report an average operational cost reduction of 40% compared to their traditional counterparts, making this technology highly attractive for manufacturers aiming for sustainable practices.

Additionally, the longevity of UV LED lights contributes further to cost reduction. With a lifespan of over 20,000 hours, these LEDs outlast conventional UV lamps, which typically require replacement every 1,000 hours. As a result, manufacturers benefit from decreased maintenance and replacement costs. Research shows that the efficiency of UV LED technology not only enhances productivity but also significantly reduces the carbon footprint, aligning with global efforts for sustainable manufacturing and energy efficiency in accordance with recent advancements seen in photovoltaic technology and energy-efficient designs across various sectors. This synergy of innovation and sustainability positions UV LED curing as a pivotal solution for modern industrial challenges.

In modern manufacturing, the implementation of UV LED curing equipment is revolutionizing production processes, particularly by significantly speeding up operations. Unlike traditional curing methods, UV LED technology allows for rapid drying and curing of inks, coatings, and adhesives, drastically reducing cycle times and enhancing overall workflow efficiency. Recent predictions suggest that the UV curing system market is projected to reach USD 23.47 billion, highlighting the growing demand and acceptance of this technology across various industries.

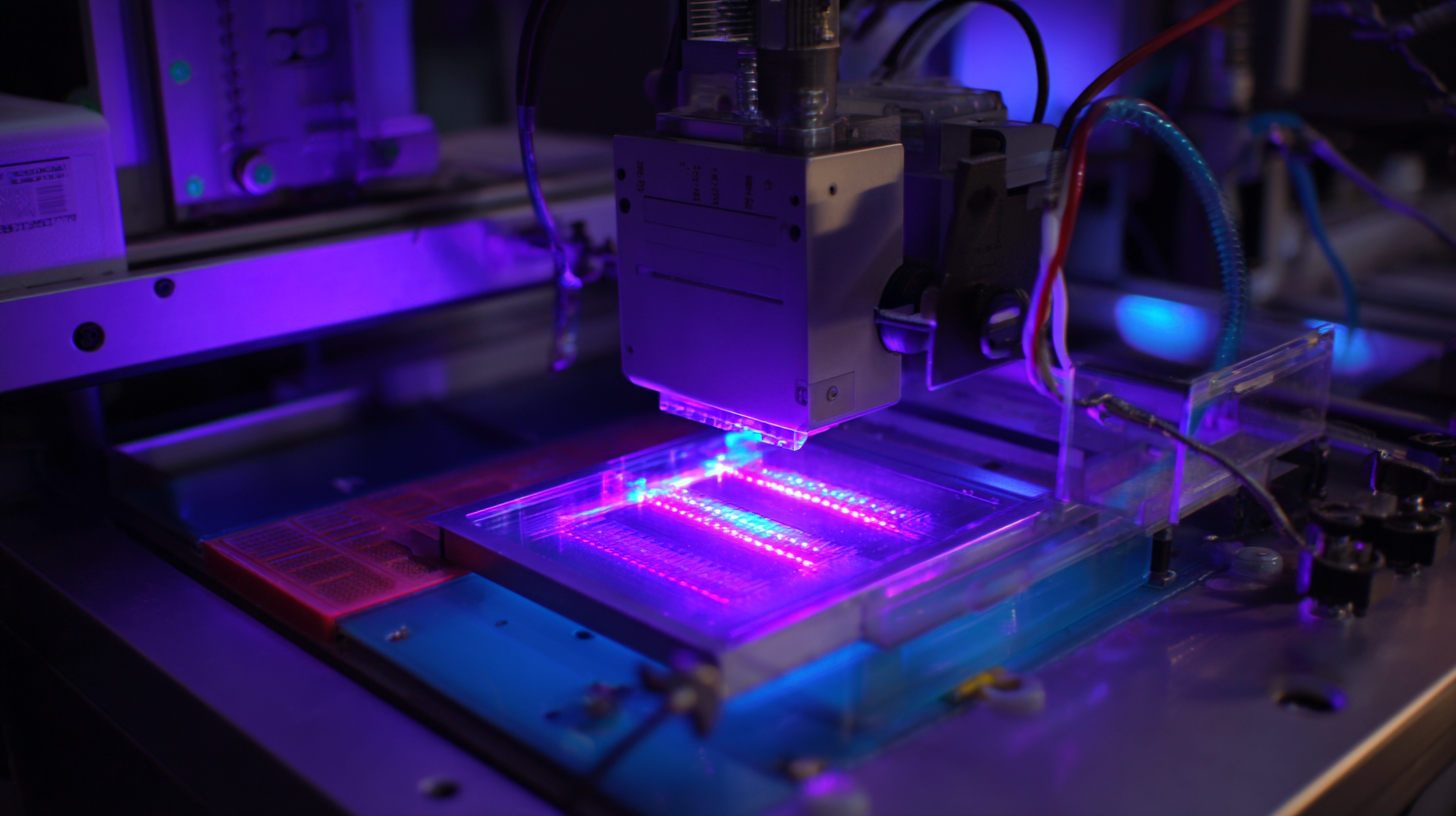

One notable advancement is the use of rapid, continuous additive manufacturing techniques, which aim to address the inadequacies of layer-wise fabrication. By utilizing volumetric polymerization inhibition patterning, manufacturers can achieve higher production speeds and maintain quality, making UV LED curing an integral part of this process. As more companies prioritize efficiency, the application of UV curing in automotive and packaging sectors is becoming increasingly prominent, offering a solution to operational delays historically caused by long curing times.

**Tip:** To maximize the benefits of UV LED curing, consider routine maintenance of equipment to ensure optimal performance and longevity. Additionally, staying updated with the latest advancements in UV curing technology can further enhance production capabilities and quality outputs. Investing in training for operators can also ensure efficient utilization of these systems, which is vital in maintaining a competitive edge in the market.

| Feature | Advantage | Impact on Production |

|---|---|---|

| Curing Speed | Rapid curing time | Increases throughput |

| Energy Efficiency | Lower energy consumption | Reduces operating costs |

| Minimal Heat Generation | Protects heat-sensitive substrates | Ensures product integrity |

| Longevity | Long lifespan of LEDs | Decreases maintenance frequency |

| Quality of Finish | Superior gloss and adhesion | Enhances product quality |

The adoption of UV LED curing equipment in modern manufacturing processes offers significant environmental advantages that cannot be overlooked. Unlike traditional curing methods, which often rely on high-energy consumption and produce substantial volatile organic compounds (VOCs), UV LED technology provides a cleaner, more efficient alternative. The energy efficiency of UV LED systems results in lower electricity usage, reducing the overall carbon footprint associated with manufacturing activities.

Moreover, UV LED curing processes emit minimal heat compared to conventional systems, leading to less thermal distortion of materials and decreased cooling requirements. This reduced heat output not only conserves energy but also diminishes the need for additional air conditioning in production facilities, further supporting sustainability efforts. By limiting the release of harmful byproducts and minimizing energy consumption, UV LED curing equipment plays a critical role in fostering environmentally friendly manufacturing practices, making it an essential investment for companies aiming to enhance their ecological responsibility.

UV LED curing equipment has revolutionized manufacturing, offering unmatched versatility across various industries and applications. From automotive to electronics, this technology enables rapid curing of coatings, inks, and adhesives, providing efficiency without compromising quality. Unlike traditional curing methods, UV LED systems operate at lower temperatures, reducing the risk of heat damage to sensitive components, making them ideal for intricate designs.

**Tip:** When selecting UV LED curing equipment, consider the specific materials and substrates you’ll be working with. Different LED wavelengths may be needed to effectively cure certain inks and coatings.

In the packaging industry, UV LED curing enhances print quality and durability, leading to longer-lasting labels and packaging. Its eco-friendly nature, characterized by reduced VOC emissions, further aligns with sustainable manufacturing practices. Additionally, in the furniture and woodworking sectors, UV LED curing allows for quick turnaround times, enabling manufacturers to meet tight deadlines while maintaining high standards.

**Tip:** To maximize the efficiency of UV LED curing, ensure proper alignment of the curing unit with the item being cured, as this can significantly affect the curing speed and uniformity of the application.

This chart illustrates the versatility of UV LED curing technology across various industries and applications. The data shows the percentage of adoption rates in different sectors, reflecting the growing trend towards UV LED curing due to its efficiency and environmental benefits.