Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When exploring the world of nail art and printing, the right tools are essential. One such tool is the LED UV curing lamp. These lamps are transforming the way we cure gel polishes and inks. With various options available, choosing the best LED UV curing lamp can be challenging yet rewarding.

Consider factors like wattage, bulb type, and size when selecting your lamp. A higher wattage often leads to quicker curing times. However, not all high-wattage lamps are created equal; some may not distribute light evenly. This means some areas may not cure properly, leaving you with imperfections.

It's necessary to evaluate your specific needs and applications. Do you require a portable option or a larger, more powerful model? Reflect on your usage patterns and budget. Ultimately, making a thoughtful decision will enhance your projects and satisfaction with the outcomes. Your journey towards the ideal LED UV curing lamp might not be perfect, but the effort is surely worthwhile.

LED UV curing is revolutionizing various industries, from printing to wood finishing. This technology uses ultraviolet light to cure or harden materials quickly. The impact is significant: recent market reports indicate a projected growth of over 15% annually in the LED UV curing sector, emphasizing its increasing importance.

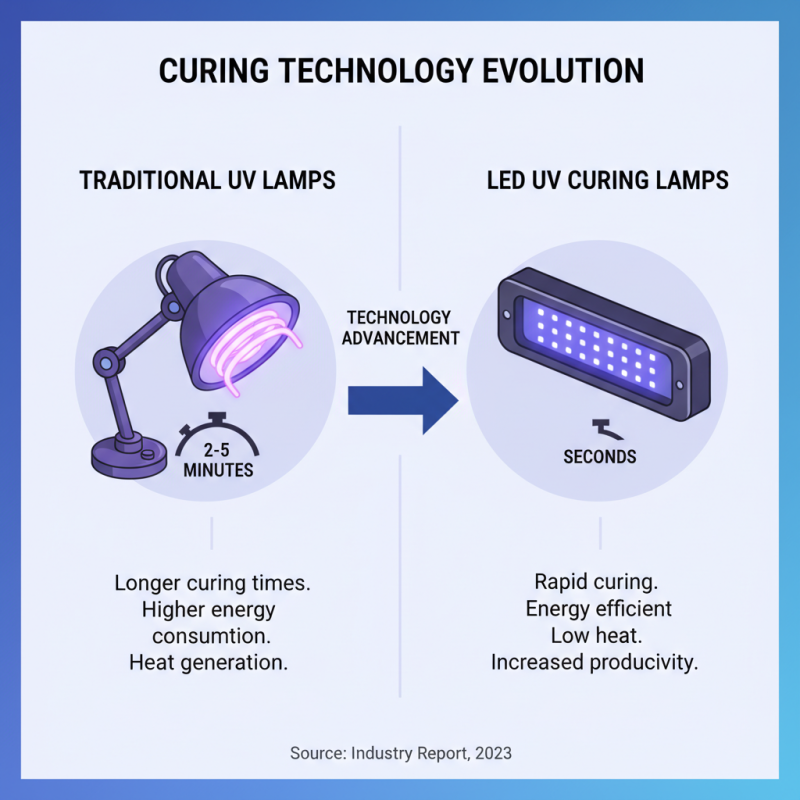

One of the key benefits of LED UV curing is energy efficiency. These lamps consume about 80% less energy compared to traditional UV lamps, leading to reduced operational costs. Moreover, they have a longer lifespan, lasting up to 20,000 hours. However, the initial cost can be higher than traditional options. It's essential to evaluate budget limitations against potential savings.

Understanding the curing process is complex. For instance, some materials may not respond well to LED curing. Certain inks and coatings might require adjustments in formulation. This complexity can lead to trial and error. However, with the proper knowledge, the benefits of speed and efficiency often outweigh these challenges. Adapting your processes may take time, but the rewards are clear in productivity and sustainability.

| Model | Wattage | Curing Time (seconds) | Wavelength (nm) | Weight (lbs) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 36W | 15 | 365 | 3.5 | $120 |

| Model B | 48W | 10 | 395 | 4.2 | $150 |

| Model C | 24W | 20 | 365 | 2.8 | $80 |

| Model D | 54W | 8 | 405 | 5.0 | $180 |

| Model E | 30W | 12 | 375 | 3.0 | $100 |

When looking for the right LED UV curing lamp, it's essential to understand the types available. There are various styles suited for different applications. These lamps vary in intensity, wavelength, and design to meet specific needs.

First, you'll find handheld LED UV lamps, perfect for small projects. They are portable and easy to use. Ideal for nail curing or small craft tasks, they offer flexibility. Then, there are larger desktop models designed for industrial use. These require more space but cure quickly and efficiently. They are often equipped with multiple wavelength settings, which can be beneficial.

Lastly, specialized units exist for particular applications. Some lamps focus on thicker surfaces, while others are tailored for delicate materials. While selection is vast, it’s crucial to consider your specific needs. Not every lamp will suit every purpose. Testing different models can be helpful. Many people overlook the importance of compatibility with materials, leading to unsatisfactory results. Finding the right balance may take time and patience.

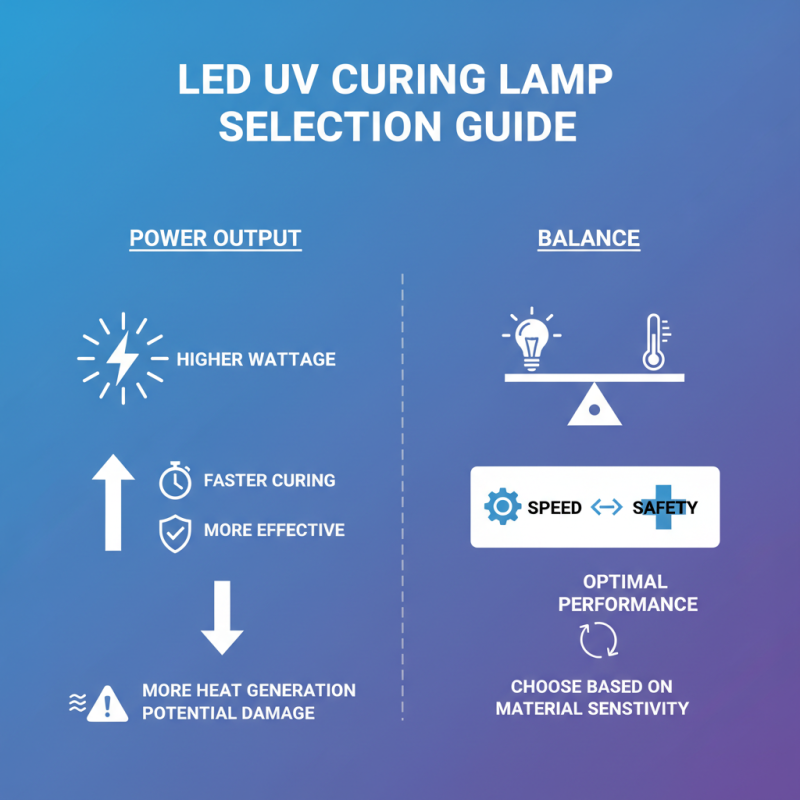

When selecting an LED UV curing lamp, several key features deserve attention. Power output is critical. A higher wattage can cure materials faster and more effectively. However, it may generate more heat, which can damage sensitive items. Strike a balance between speed and safety.

The size of the lamp matters too. A compact lamp may be more convenient for small projects, but it might not accommodate larger surfaces. When choosing, consider both the workspace and the types of materials used. Compatibility with various substrates is essential, so verify that the lamp works with the inks or coatings you plan to use.

Lastly, think about the lamp's lifespan. LED lamps generally last longer than traditional UV lamps, but quality varies. A shorter lifespan may appear cost-effective initially, but will lead to frequent replacements. Reflect on your long-term needs and choose accordingly.

LED UV curing lamps have significantly changed the landscape of curing technology. Unlike traditional options, LED lamps use a specific wavelength that allows for faster curing times. According to a recent industry report, LED lamps can cure materials in seconds, while traditional UV lamps may take minutes. This difference can boost productivity in various applications, including printing and coating processes.

Efficiency is another strong point for LED lamps. They consume less energy, resulting in lower operational costs. The EcoVadis report indicates that businesses can save up to 50% on energy consumption with LED technology. This not only benefits the environment but also reduces overhead costs for manufacturers. However, one shouldn't overlook the initial investment in LED equipment, which can be higher than traditional options.

Tip: When selecting a curing lamp, consider the specific wavelength requirements of your materials. Using the wrong wavelength can lead to suboptimal curing results.

While LED lamps offer many advantages, they also come with challenges. For instance, not all materials are compatible with LED curing. Users must test their specific applications to avoid issues. It’s essential to conduct thorough research and testing before fully transitioning to LED technology.

Tip: Keep track of your suppliers and ensure they provide tested materials for LED curing. This can prevent wasted time and resources.

When selecting an LED UV curing lamp, consider your specific application. Different tasks require different specifications. For nail salons, a lamp with a wide spectrum is essential. This ensures all types of gel polish cure properly. For industrial applications, you may need a lamp with higher intensity. This allows for faster curing times on various materials.

**Tips:** Always check the lamp's wavelength. This affects how effectively it cures your materials. A mismatch can lead to under-curing, which is problematic.

Look at the lamp's size and portability. Some projects require moving the lamp around. If your workspace is tight, a compact model may be more suitable. However, a larger lamp can cover more area at once, improving efficiency.

**Tips:** Don’t forget to consider power consumption. Some high-intensity lamps might consume more electricity. Weigh the trade-offs between speed and energy usage. A balance is essential for energy efficiency over time.