Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the world of adhesive solutions, the "Uv Glue Curing Lamp" plays a critical role in achieving strong bonds. Dr. Emily Thompson, a leading expert in adhesive technology, states, "The right UV curing lamp can transform your bonding process completely." This emphasizes the importance of selecting the right equipment in this industry.

Utilizing a top-notch Uv Glue Curing Lamp can enhance speed and efficiency. Many users report quicker curing times, which means they can complete projects faster. However, choosing the wrong lamp may result in weak bonds, causing frustrations down the line. It's essential to understand the specific needs of your application.

While many products flood the market, a discerning eye is required. Not every Uv Glue Curing Lamp is created equal. Features like wavelength, intensity, and design matter significantly. Some products may promise efficiency but fall short in practice. It’s crucial to conduct thorough research before making a decision. Balancing budget against quality can be challenging, but the right choice leads to improved results.

UV glue has gained popularity across various industries due to its unique properties. This adhesive relies on ultraviolet light to cure and bond materials. Common applications include electronics, automotive, and woodworking. According to a report by Transparency Market Research, the UV adhesive market is projected to reach USD 3.4 billion by 2026, growing at a CAGR of 8.5%. This growth highlights the increasing acceptance of UV glue in diverse bonding solutions.

Understanding how UV glue works is essential for effective use. When exposed to UV light, the adhesive undergoes a photochemical reaction, rapidly curing and forming a strong bond. This process is advantageous for time-sensitive projects. However, not all materials react equally to UV glue. Some surfaces may require additional preparation or specific curing times. In practice, users must test various methods to find the right combination.

Furthermore, the efficiency of UV bonding largely depends on the curing lamp used. Quality lamps emit specific wavelengths that optimize curing. Yet, not all setups will deliver consistent results. Users often face challenges such as uneven application or lamination issues. Continuous improvement and testing are crucial for overcoming these obstacles in the quest for ideal adhesion solutions.

When selecting a UV glue curing lamp, certain key features are essential for effective bonding solutions. The wavelength of the UV light plays a crucial role. Most adhesives require specific wavelengths to cure efficiently. A lamp emitting light in the 365-405 nm range is often ideal for standard UV glues. However, some materials need tailored wavelengths for optimal results. It's crucial to verify compatibility before making a purchase.

Consider the intensity of the UV light as well. Reports show that the curing rate significantly increases with higher intensities. A UV lamp should provide at least 200 mW/cm² for efficient curing. Yet, not all tasks require the highest intensity. Understanding the specific needs of your project can lead to better decisions. Some users may overlook this and end up with underperforming results.

Portability and ease of use also matter. A lamp that is lightweight and features a user-friendly design will enhance workflow. Many cannot afford downtime. Features like adjustable timers and consistent UV output can greatly improve efficiency. However, users often take these for granted. Choosing the right UV glue curing lamp can make or break a project. Emphasizing these aspects can lead to successful bonding and ultimately, satisfied clients.

| Feature | Description | Rating (out of 5) |

|---|---|---|

| Wavelength | Optimal UV wavelength for curing glue, typically around 365nm or 405nm. | 4.5 |

| Power Output | Higher wattage allows faster curing times. | 4.7 |

| Portability | Lightweight and easy to carry, ideal for fieldwork. | 4.3 |

| Timer Settings | Programmable timer for optimal curing duration. | 4.4 |

| Safety Features | Includes protective features like auto shut-off and UV shielding. | 4.6 |

When selecting a UV glue curing lamp, many factors come into play. The intensity of the light is crucial for effective bonding. Some lamps emit a wide spectrum, while others focus on specific wavelengths. A lamp with adjustable intensity offers versatility, allowing users to handle various materials. This feature can enhance the curing process and improve adhesion.

The design of the lamp can also greatly affect usability. Compact models are easy to store and transport. However, they may struggle with larger projects. Lamps with timers can also be beneficial, automating the curing process. Users sometimes overlook the importance of portability in their selection.

Durability and build quality are other critical factors. Some lamps may stop working efficiently after limited use. Users should be cautious about this. Not every lamp is designed for prolonged exposure to UV light. Watching for signs of wear can help identify issues early on. Ultimately, while many factors influence the choice, it's essential to prioritize personal needs and project requirements.

When using UV glue curing lamps, proper techniques greatly enhance bonding efficiency. A

2022 report from the Adhesives and Sealants Council emphasized that up to

70% of adhesive failures arise from improper curing. This statistic highlights the need to

optimize UV exposure times and lamp positioning. Direct exposure to the glue is crucial. However, many users overlook the importance

of maintaining a consistent distance. An inconsistent distance can lead to uneven curing, weakening the bond integrity.

Additionally, the choice of UV wavelength plays a significant role. A study from the

Polymer Science Journal found that different adhesives respond best to specific wavelengths. For instance, some adhesives cure

optimally around 365 nm. Many users default to a single wavelength lamp, which can

limit bonding effectiveness. Variability in adhesive properties often requires experimentation.

Users should regularly assess their bonding results and adjust methods.

Environmental factors also influence curing efficiency. Humidity and temperature

can alter adhesive performance. Users frequently underestimate these variables, which can lead to inconsistent results.

Monitoring these conditions ensures better control over the curing process. Regular reflection on these practices allows for

continual improvement and better bonding outcomes.

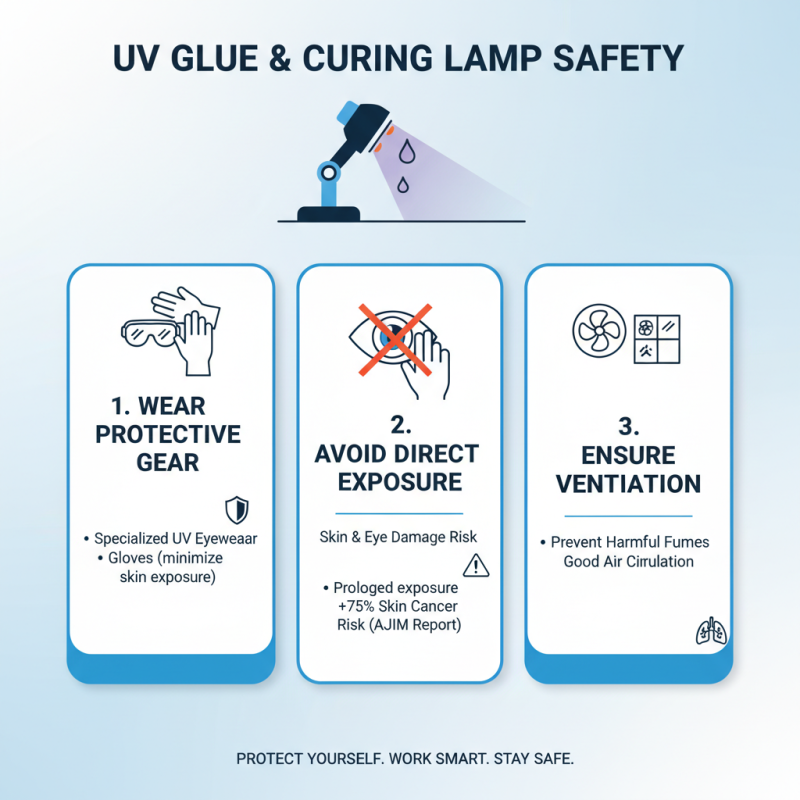

When using UV glue and curing lamps, safety must be a top priority. UV light can cause skin and eye damage if not properly managed. According to a report by the American Journal of Industrial Medicine, prolonged exposure to UV radiation increases the risk of skin cancers by 75%. Users should always wear protective gear, including specialized eyewear and gloves, to minimize these risks. The importance of well-ventilated workspaces cannot be overstated. Poor air circulation can lead to harmful fumes accumulating.

Handling UV glues requires careful attention as well. Many products contain hazardous solvents that can irritate the skin and respiratory system. Data from the Environmental Protection Agency indicates that exposure to volatile organic compounds (VOCs) can cause headaches, dizziness, and long-term health issues. Users should review safety data sheets (SDS) carefully to understand the chemical composition and safety advice for each product. It’s essential to use these materials in controlled environments, ensuring proper disposal of any waste.

Reflecting on this, many users might overlook the importance of safety protocols in pursuit of efficiency. This can lead to accidents that are both painful and costly. A report by the National Safety Council highlights that improper use of safety equipment resulted in thousands of workplace injuries last year. Thus, awareness and learning from these incidents can lead to improved practices in UV glue applications.