Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

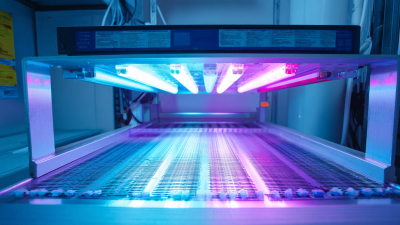

The adoption of UV LED curing light technology is rapidly transforming various industries, from printing to automotive coatings, thanks to its energy efficiency and rapid curing capabilities. According to a report by Smithers Pira, the global market for UV curing is projected to reach $4.3 billion by 2027, highlighting the growing reliance on this technology. However, businesses utilizing UV LED curing light face several significant challenges that can impact performance and operational efficiency. These challenges range from high initial investment costs and the need for specialized equipment to the complexities of achieving optimal curing conditions for different materials. As organizations navigate this evolving landscape, understanding these hurdles is crucial for maximizing the benefits of UV LED curing light technology while mitigating potential setbacks.

The adoption of UV LED curing technology has revolutionized various industries, offering faster curing times and energy efficiency. However, one of the primary challenges businesses face is the initial investment required to implement this advanced technology. The cost of UV LED curing equipment can be significantly higher than traditional UV lamp systems, which can deter companies from making the leap to this innovative solution.

Despite the long-term cost savings and benefits, such as reduced energy consumption and lower heat production, many businesses are hesitant to invest upfront. This initial financial burden can strain budgets, particularly for small and medium-sized enterprises that may lack the capital for significant technological upgrades. Additionally, companies must consider the potential costs of training staff to operate the new equipment effectively, which can further complicate the decision-making process.

Ultimately, while the advantages of UV LED curing technology are compelling, the impact of initial costs creates a barrier that businesses must navigate carefully. The challenge lies in weighing short-term expenses against long-term savings, as well as in understanding the potential market advantages gained from improved production efficiency.

The integration of UV LED curing light technology into business operations presents a myriad of technical complexities that can pose significant challenges. One primary issue is the need for specialized knowledge in both the hardware and software components associated with UV LED systems. According to a report by the National Institute of Standards and Technology (NIST), improper handling or understanding of UV LED systems can lead to suboptimal curing processes, affecting product quality and increasing waste by up to 20%. This highlights the necessity for ongoing training and education for employees working with these advanced technologies.

Additionally, the variability in UV LED light output is another major technical hurdle. Unlike traditional curing methods, which often have a broader spectrum of light, UV LEDs emit specific wavelengths that can affect curing times and adhesion properties. A study conducted by the Radtech organization found that businesses using UV LED systems often experience inconsistencies in performance, depending on the materials and applications used. Such technical unpredictability can hinder production timelines and challenge manufacturers to maintain stringent quality control measures. As companies transition to UV LED technology, understanding these complexities becomes essential for maximizing efficiency and achieving desired outcomes.

The application of UV LED curing light technology presents unique challenges for businesses, particularly regarding material compatibility. As companies adopt this innovative curing method to enhance efficiency and reduce environmental impact, they must navigate the complexities of various substrates and coatings. Different materials react differently to UV light, and inconsistencies can lead to subpar results, including inadequate curing or, conversely, over-curing, which can compromise the integrity of the final product.

To manage this variability, businesses should conduct thorough testing across all materials intended for use with UV LED systems. Understanding the spectral sensitivity of different inks, coatings, and substrates is crucial in identifying the best combinations for optimal curing. Moreover, collaborating with manufacturers and suppliers can provide insights into material formulations that are specifically designed for UV LED technology. By proactively addressing these compatibility issues, businesses can harness the full potential of UV LED curing light, ensuring consistent quality and reducing waste in their production processes.

The adoption of UV LED curing light technology in various industries, including printing and coatings, has surged due to its energy efficiency and rapid cure times. However, alongside these benefits come significant health and safety concerns that must be addressed. According to a report by the International Ultraviolet Association, prolonged exposure to UV radiation can lead to skin and eye injuries, raising alarm among workers in environments where UV LED curing is prevalent.

To mitigate these risks, manufacturers are implementing stringent safety protocols, including barrier systems, protective equipment, and enhanced ventilation. A study published by the Occupational Safety and Health Administration (OSHA) highlights that appropriate personal protective equipment (PPE) can reduce the risk of UV-induced injuries by over 50%. Additionally, regular training sessions on safety practices further ensure that employees are aware of potential hazards. As the industry grows, ongoing research and innovation in safety measures will be crucial in sustaining the benefits of UV LED curing while protecting the workforce from health risks.

When integrating UV LED curing light technology into their operations, businesses often encounter significant challenges related to workforce training. The effective use and maintenance of UV LED systems require a skilled workforce that understands the nuances of the technology. According to a report by Smithers Pira, nearly 60% of companies reported that inadequate training had hindered their productivity when transitioning to UV LED curing processes. This emphasizes the necessity for ongoing training programs that not only cover operational procedures but also delve into troubleshooting and maintenance protocols.

To address these challenges, companies are encouraged to establish comprehensive training modules that incorporate hands-on experience with UV LED equipment. Implementing regular workshops and certification programs can enhance employee confidence and competence. For example, a study by the RadTech organization highlights that firms with robust training regimens saw a 25% reduction in equipment downtime, significantly improving overall efficiency.

**Tips:** Invest in a mix of theoretical and practical training sessions for employees, focusing on both operation and maintenance. Additionally, create a resource library with instructional videos and manuals that staff can refer to as needed. Finally, encourage a culture of continuous learning where employees can share insights and improvements based on real-world experiences with the technology.