Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

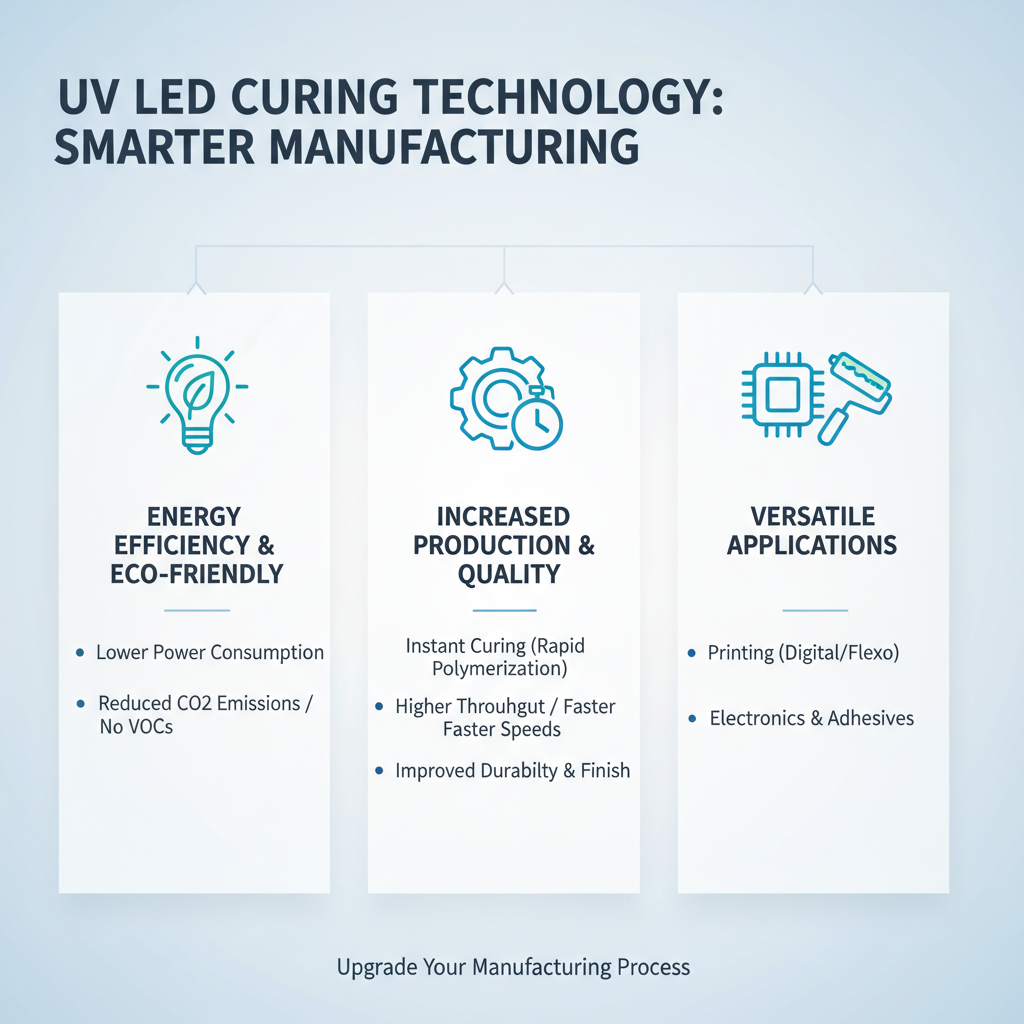

In the rapidly evolving landscape of industrial technologies, the adoption of UV LED curing equipment has surged, driven by the demand for efficient, sustainable, and high-quality production processes. According to a recent report by Allied Market Research, the global UV LED market is projected to reach $3.5 billion by 2025, growing at a compound annual growth rate (CAGR) of over 35% from 2020. This exponential growth underlines the increasing reliance on UV LED curing equipment across various sectors, including automotive, electronics, and packaging.

Choosing the right UV LED curing equipment for your business is crucial, not just for enhancing operational efficiency but also for ensuring environmental compliance and reducing energy consumption. Purchasing decisions are influenced by factors such as cure speed, cost-effectiveness, and compatibility with existing systems. A study by MarketsandMarkets highlighted that businesses utilizing UV LED technology reported energy savings of up to 50% compared to traditional curing methods, showcasing its economic and ecological benefits.

Investing in UV LED curing equipment is not merely a trend; it is a strategic move that can position your business at the forefront of innovation. As the industry continues to evolve, understanding the key variables in selecting the best UV LED curing solutions will be essential for achieving competitive advantage and long-term sustainability.

In today’s evolving manufacturing landscape, understanding UV LED curing technology is crucial for businesses looking to enhance their production efficiency and quality. UV LED curing uses ultraviolet light to initiate polymerization, allowing coatings, inks, and adhesives to cure rapidly. Unlike traditional curing methods that rely on heat, UV LED technology offers significant advantages such as lower energy consumption and reduced emissions, making it an environmentally friendly option for various industries, including printing, woodworking, and electronics.

The basics of UV LED curing involve several key components: the UV LED lamps, the photoinitiators in the materials, and the substrate being cured. UV LED lamps emit specific wavelengths of light that activate these photoinitiators, initiating a chemical reaction that hardens the material. This process not only speeds up production times but also improves the durability and performance of the final product. As businesses explore the best UV LED curing equipment, understanding these fundamentals will aid in making informed decisions tailored to their specific operational needs.

When selecting UV LED curing equipment for your business, understanding your specific needs is crucial. Begin by evaluating the types of materials you will be working with. Different substrates, such as plastics, metals, or glass, may require distinct curing technologies and equipment specifications. Knowing the compatibility of your materials with UV LED technology will help in determining the appropriate machine that can effectively cure your products without compromising quality.

Next, consider the scale and speed of your operations. If your business demands high-volume production, investing in a more robust and faster curing system would be beneficial. Assess the size of your production line and the available space for new equipment. Additionally, think about the desired output speed and efficiency you aim to achieve. By aligning the equipment's capabilities with your operational goals, you can enhance productivity while maintaining cost-effectiveness, ultimately leading to better business performance.

When selecting UV LED curing equipment for your business, it's essential to focus on several key features that can enhance your production efficiency and quality. One of the most important aspects is the wavelength of the UV light. Different materials require specific wavelengths for optimal curing, so ensure the equipment you choose offers a variety of wavelengths suitable for your applications.

Another critical feature to consider is the power output. Higher power levels can lead to faster curing times, but also assess how the output affects the quality of the cured surface. Consistent and uniform light distribution is crucial for achieving the best results across your entire workpiece.

**Tips:** Always request a demonstration of the equipment to see the curing process in action. Evaluate the maintenance requirements as well; equipment that is easy to clean and maintain will save you time and costs in the long run. Lastly, don’t overlook the importance of warranty and customer support when making your decision; reliable assistance can make a significant difference in your operations.

When selecting the best UV LED curing equipment for your business, it's essential to compare different brands and models to find the perfect fit for your specific needs. Various manufacturers offer equipment with diverse features, wattages, and curing speeds. For instance, some brands may excel with portable options ideal for smaller operations, while others provide robust systems designed for high-volume production. Evaluating these differences can help streamline your workflow and increase productivity.

**Tips:** Consider the level of customer support and warranty offered by manufacturers, as reliable assistance can save you time and money in the long run. Additionally, check for compatibility with the materials you plan to cure, as not all systems perform well with every substrate.

Furthermore, don’t overlook the energy efficiency of the models you’re interested in. Many leading brands now incorporate features that minimize power consumption without compromising on curing performance. This not only helps reduce operational costs but is also advantageous for environmentally conscious businesses.

**Tips:** Read customer reviews and case studies to gain insight into the real-world performance and reliability of the UV LED curing systems under consideration. This valuable information can guide your decision-making process and ensure you choose the best equipment for your business needs.

This chart compares the UV LED curing equipment based on three key performance indicators: Curing Speed (cm/min), Energy Consumption (W), and Equipment Cost (USD). The data represents hypothetical figures to illustrate the differences in performance across various models.

When considering the purchase of UV LED curing equipment for your business, budget considerations play a critical role. Initially, businesses must evaluate the upfront costs of the equipment, including installation and any necessary accessories. While UV LED systems often come with a higher price tag compared to traditional curing methods, their energy efficiency and longevity can lead to significant cost savings over time. It's essential to analyze not only how much you will spend but also how these systems can reduce operational costs, such as energy consumption and maintenance.

Moreover, calculating the return on investment (ROI) for UV LED equipment is crucial. A thorough ROI analysis should encompass not only the direct financial implications but also the potential gains in production efficiency and product quality. Faster curing times can lead to improved throughput, allowing your business to meet increased customer demand without sacrificing quality. By assessing both the short-term expenditures and the long-term benefits, you can make a more informed decision that aligns with your business goals and financial strategies.

| Criteria | Details | Estimated Cost ($) | Expected ROI (%) |

|---|---|---|---|

| Wattage | Power level required for your production line | 2,000 - 10,000 | 20% |

| Curing Speed | Time taken to cure products | 1,500 - 3,500 | 25% |

| Maintenance Requirements | Frequency and cost of maintenance | 500 - 1,500 | 15% |

| Energy Efficiency | Energy consumption per unit produced | 1,200 - 2,800 | 30% |

| Initial Investment | Cost to purchase equipment | 10,000 - 50,000 | 50% |