Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As the demand for advanced dental and medical treatments continues to rise, the importance of reliable and efficient LED curing lamps cannot be overstated. In the field of dentistry, research has shown that the global LED curing lamp market is projected to reach approximately $600 million by 2025, reflecting a compound annual growth rate (CAGR) of over 5% from 2020. This growth underscores the necessity for practitioners to select the best equipment tailored to their specific needs.

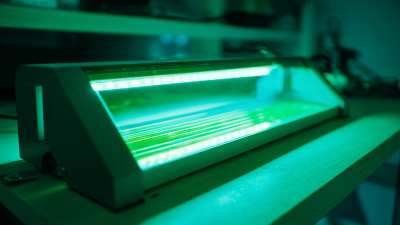

LED curing lamps are critical tools utilized in a variety of applications, including dental restorations, orthodontics, and cosmetic procedures. Their efficiency in polymerizing dental resins and composites significantly impacts the quality and longevity of dental work. As the technology evolves, an array of products with varying specifications, wavelengths, and curing times becomes available, making it imperative for industry professionals to stay informed about the latest developments and innovations.

Choosing the right LED curing lamp not only affects operational outcomes but also enhances patient satisfaction through improved treatment efficacy. Therefore, understanding how to effectively evaluate these devices will be vital for practitioners seeking the best solutions moving towards 2025 and beyond.

When selecting LED curing lamps, several key factors come into play to ensure you choose the best option for your specific needs. First and foremost, consider the wavelength of the LED lamp. Different applications require different wavelengths; for example, dental curing typically uses a wavelength of around 400-500 nm, while certain industrial applications might require more specialized wavelengths. Additionally, assess the intensity and output power of the lamp, as these directly affect curing speed and efficiency. A higher intensity usually translates to faster curing times, which can significantly enhance productivity.

Another important factor is the durability and lifespan of the LED curing lamp. As LED technology improves, many products now offer extended lifespans, reducing the need for frequent replacements. Look for lamps with good thermal management systems to ensure that they operate efficiently without overheating, which can impact performance and longevity. Furthermore, consider the ease of use and mobility, especially if the lamp will be used in different locations or need to be transported frequently. These elements collectively influence the overall effectiveness and practicality of LED curing lamps for both professional and personal use.

The selection of the best LED curing lamps for your needs in 2025 requires an understanding of the competitive landscape and key performance indicators. According to a recent report by Grand View Research, the global UV LED market is projected to reach approximately $3.6 billion by 2025, with a compound annual growth rate (CAGR) of 34.5%. This growth highlights the increasing demand for efficient and versatile curing solutions across various industries such as dental, automotive, and printing.

When comparing the top five LED curing lamps in 2025, several features stand out. These include the lamp’s wavelength, intensity output, and curing times. For example, lamps that emit light within the 385-405 nm wavelength range have been shown to cure materials more effectively, as supported by data from the Journal of Photopolymer Science and Technology. Additionally, the intensity of the lamp, measured in mW/cm², plays a critical role in determining the speed of the curing process. A study indicated that lamps with an intensity greater than 1,500 mW/cm² resulted in significantly faster curing times without compromising the quality of the bond. By focusing on these critical metrics, users can make informed decisions tailored to their specific applications.

When choosing LED curing lamps, understanding the various wavelengths available is crucial, as different wavelengths have a significant impact on the curing process. LED lamps emit light in specific wavelengths, typically ranging from 395 to 455 nanometers, which are optimal for curing different materials. For example, a wavelength around 405 nm is commonly used for curing dental resins and some adhesives, as it effectively activates the photoinitiators present in these materials. Understanding which wavelength aligns with your specific needs can enhance adhesive qualities and ensure a more efficient curing process.

Moreover, the intensity and penetration power of the emitted light can vary with wavelength, influencing the curing time and outcome. Shorter wavelengths tend to provide deeper penetration and faster curing but may lead to heat generation that could potentially damage sensitive materials. Conversely, longer wavelengths may cure more slowly but are often gentler on heat-sensitive applications. Therefore, when selecting an LED curing lamp, consider not just the wavelength but how it matches with the type of materials you intend to cure, as well as the specific requirements of your work environment.

When selecting the best LED curing lamp for your needs, budgeting plays a crucial role. While it’s tempting to opt for the lowest-priced option available, it’s important to weigh cost against performance. Cheaper lamps might save you money upfront, but they can compromise on curing efficiency, which means you may need to spend more in the long run due to repeated applications or slower processing times. Investing in a high-quality LED curing lamp can pay off with faster curing cycles, enhanced durability, and better results.

Performance metrics to consider include irradiation intensity, wavelength specificity, and the lamp's lifespan. Higher-end models are often designed with advanced features that enhance performance, such as customizable curing modes and better heat management. While these features may increase the initial cost, they contribute to greater efficiency and reliability. Therefore, a balanced approach to budgeting—one that considers both immediate costs and long-term value—will guide you to make an informed decision when choosing the right LED curing lamp for your specific applications.

When selecting LED curing lamps, maintenance and longevity should be at the forefront of your decision-making process. A recent industry report indicates that high-quality LED curing lamps can last up to 25,000 hours compared to traditional curing methods, which typically require replacement after only 1,000 hours. This substantial difference not only reduces replacement costs but also minimizes downtime in professional settings, enhancing productivity and efficiency.

To ensure durability, choose LED curing lamps with durable housing materials and robust thermal management systems. These features can significantly extend the lifespan of the lamps. Regular maintenance, including cleaning the lens and replacing filters as needed, is essential. According to studies, keeping the lamp clean can improve its efficiency by up to 30%, ensuring that you get the most out of your investment.

**Tips:** Always check for warranty and service options when purchasing LED curing lamps. Look for products that provide a minimum two-year warranty, as this often reflects the manufacturer’s confidence in the lamp's durability. Additionally, consider investing in models equipped with smart technology that alerts users to maintenance needs, further enhancing longevity and performance.