Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the use of UV drying lights has gained significant traction across various industries, including printing, woodworking, and automotive finishing. According to a report by Smithers Pira, the UV curing market is projected to reach $3.5 billion by 2025, driven by its efficiency and speed in drying and curing processes. As industries strive for faster production times and environmentally friendly solutions, understanding how to choose the best UV drying light for specific projects becomes essential.

Dr. Emily Huang, a leading expert in UV technology, emphasizes the importance of selecting the right equipment: "The effectiveness of UV drying systems lies not just in their wattage or intensity, but in the wavelength of the emitted light tailored to the materials being cured." With various options available, from low-pressure mercury lamps to LED UV lights, it can be overwhelming for professionals and hobbyists alike to navigate this complex landscape. This guide aims to break down the critical factors to consider, ensuring that you choose the most suitable UV drying light for your unique project needs.

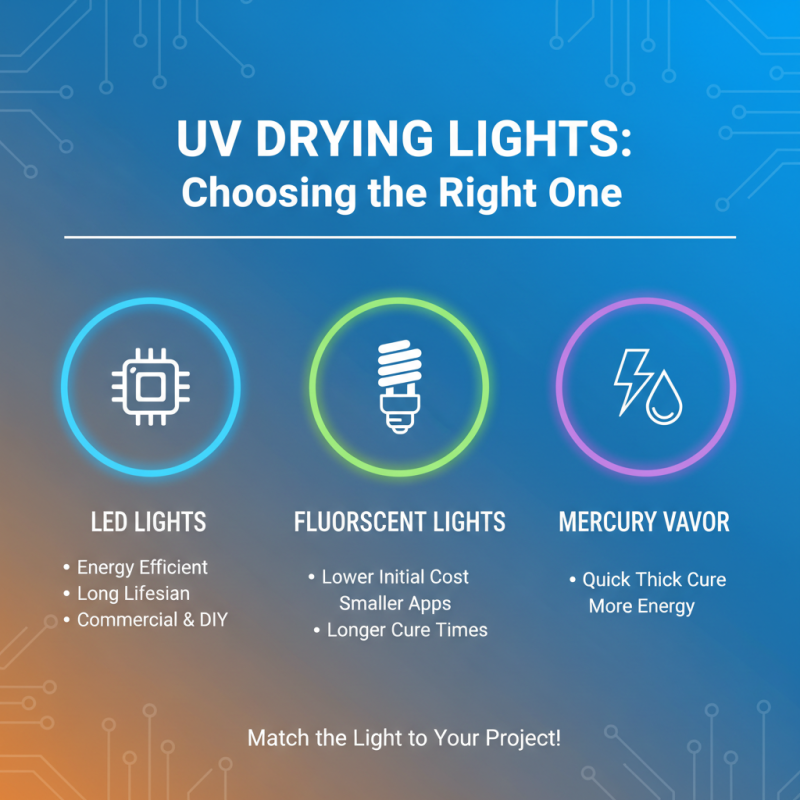

When selecting the right UV drying light for your projects, it's essential to understand the different types available and their specific applications. UV drying lights come in various forms such as LED, fluorescent, and mercury vapor lamps. LED lights are favored for their energy efficiency and long lifespan, making them ideal for both commercial and DIY projects. Fluorescent lights are often used in smaller applications due to their lower initial cost but may have longer curing times. On the other hand, mercury vapor lamps are known for their ability to cure thick layers of coating quickly but require more energy.

Tips: When choosing a UV drying light, consider the size of your workspace and the materials you will be curing. For larger projects, a more powerful light may be necessary to achieve uniform curing. Also, it is essential to evaluate the wavelength of the UV light, as different materials react better to specific wavelengths. Always ensure that the light fits the needs of your project to maximize efficiency.

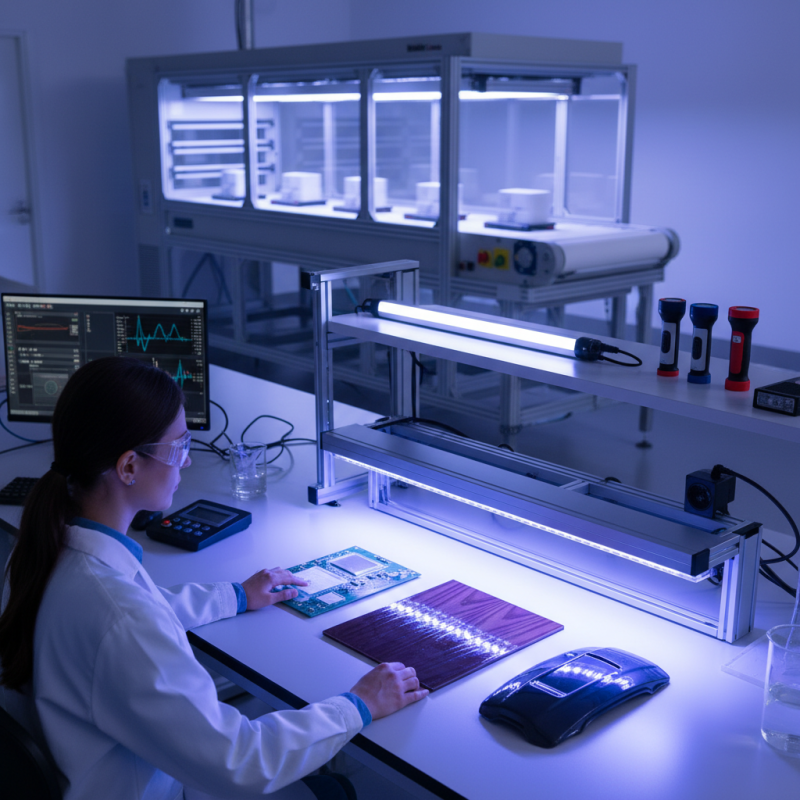

Understanding how these lights work will help you make informed decisions. The applications of UV drying lights are vast and include fields like printing, automotive, and nail art, each demanding specific characteristics from the light source. For instance, in the printing industry, UV curing can produce high-quality finishes quickly, while in nail art, a compact UV lamp is ideal for curing gel polishes efficiently. Tailoring your choice to the project at hand will ensure optimal results.

When selecting the best UV drying light for your projects, there are several key factors to consider to ensure that you make the right choice for your specific needs. First, it's essential to evaluate the type of UV light source that best suits your application. The two primary categories are UV LED and traditional ultraviolet fluorescent lamps. UV LEDs tend to be more energy-efficient, have a longer lifespan, and offer instant on-off capabilities, making them ideal for many modern applications. Conversely, fluorescent lamps may be more affordable upfront, but they come with shorter lifespans and longer warm-up times.

Another critical factor to consider is the intensity and wavelength of the UV light. The effectiveness of your drying process largely depends on the intensity of the UV radiation and its wavelength, typically measured in nanometers. Different materials and coatings cure best under specific wavelengths; hence, knowing the requirements of the materials you’ll be using is crucial. Additionally, assess the size of the drying light and the area it can effectively cover. This ensures that your project will be cured properly without having to reposition the light multiple times, which can hinder efficiency.

| Factor | Description | Recommended Range | Impact on Performance |

|---|---|---|---|

| Wavelength | The specific UV light spectrum that the lamp emits. | 280 - 400 nm | Affects curing speed and the range of materials that can be cured. |

| Power Output | The total wattage of the UV drying light. | 20 - 1000 watts | Higher wattage typically results in faster curing. |

| Curing Time | Time it takes for the UV light to complete the curing process. | Seconds to minutes | Directly influences productivity and project timelines. |

| Size and Portability | Dimensions and weight of the UV light unit. | Compact to large units | Portability aids in various project setups. |

| Safety Features | Built-in safety mechanisms to protect users. | Shielding, automatic shut-off | Ensures safe operation and minimizes risk of UV exposure. |

When selecting the best UV drying light for your projects, understanding power and intensity is crucial for achieving optimal curing results. The power output of a UV lamp, typically measured in watts, directly influences the speed and efficiency of the curing process. Industry reports indicate that UV curing systems with a power output between 200 and 600 watts per linear inch are most effective for various applications, including coatings, adhesives, and inks. Higher wattage generally results in shorter curing times, but it’s essential to balance power with the specific needs of the materials being cured.

Intensity, measured in milliwatts per square centimeter (mW/cm²), also plays a vital role in the curing effectiveness. Research shows that a minimum intensity of 200 mW/cm² is often required for optimal curing of standard UV materials. Applications that demand higher durability or resistance to environmental factors may require intensities exceeding 300 mW/cm². Additionally, the distance from the UV source to the curing surface significantly impacts the intensity; maintaining an optimal distance of 6 to 12 inches ensures adequate exposure without compromising the quality of the cure. Understanding these parameters enables professionals to select the right UV drying light for their specific project requirements, ensuring efficiency and superior results in their applications.

When selecting a UV drying light for your projects, evaluating safety features and compliance standards is crucial to ensure both effective use and protection from potential hazards. Begin by examining the light’s UL or CE certifications, which indicate that the product meets stringent safety standards. This ensures that the light has been tested for electrical safety and reliability, minimizing risks such as overheating or electrical malfunctions. Additionally, look for features such as automatic shut-off mechanisms, which can prevent accidents if the light is left on longer than necessary.

Another important aspect to consider is the presence of protective measures against UV exposure. High-quality UV drying lights often come with built-in filters or shields that mitigate harmful rays, protecting users and surrounding materials. Evaluate whether the unit includes safety goggles or other personal protective equipment, as these items can help further reduce risks associated with prolonged exposure. Lastly, consider how easy it is to access safety information and usage instructions, as clear guidelines can significantly enhance user compliance with safety protocols.

When selecting a UV drying light for your projects, understanding price points and brand reliability is crucial. According to the 2022 Industry Insights Report, the average price range for UV drying lights varies significantly, from budget options around $50 to high-end professional units exceeding $500. While affordable lights can initially seem appealing, they often lack the durability and efficiency necessary for long-term use. Investing in a reliable brand can pay dividends, as research indicates that quality equipment can enhance productivity by up to 30%, significantly reducing drying times and improving finish quality.

Tips for choosing the right UV drying light include: