Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

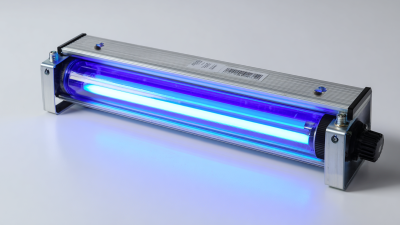

When it comes to enhancing the efficiency and quality of your business's curing processes, selecting the appropriate UV Curing Flood Lamp is crucial. This guide aims to assist you in navigating the various options available in the market, ensuring you make an informed decision that aligns with your specific business needs. Whether you're involved in printing, coating, or other applications requiring reliable curing solutions, understanding the features, specifications, and benefits of different UV Curing Flood Lamps will empower you to optimize your operations. By considering factors such as power output, wavelength compatibility, and lamp design, you can tailor your choice to improve productivity and product quality. Join us as we delve into the essential criteria to evaluate when selecting the right UV Curing Flood Lamp for your business, allowing you to harness the full potential of UV curing technology.

When selecting a UV curing flood lamp for business needs, understanding the types and applications available is crucial. Various UV curing flood lamps are designed for specific uses, such as industrial coating, printing, and adhesive bonding. According to a recent report by Custom Market Insights, the UV curing system market is projected to reach USD 23.47 billion, reflecting a strong demand driven by sectors such as packaging and automotive, which rely heavily on efficient curing processes.

Additionally, the advancement in UV LED technology has led to the development of high-power options that can effectively replace traditional mercury lamps. This shift not only enhances energy efficiency but also reduces hazardous waste, aligning with modern sustainability goals. Reports indicate that the global market for liquid crystal on silicon is expected to grow significantly, worth USD 4.67 billion by 2034, indicating a broader trend towards innovative materials and technologies that utilize UV curing processes across multiple industries. This underscores the necessity for businesses to invest in the right UV curing solutions that cater specifically to their operational requirements and sustainability objectives.

When selecting a UV curing flood lamp for your business, there are several key factors to consider. First and foremost, understand the specific application requirements. Different materials such as plastics, inks, and coatings may require varying wavelengths and intensities of UV light for optimal curing. It's essential to identify the type of UV radiation needed, which could be UVA, UVB, or UVC, based on the substrates you will be working with. This ensures efficient curing and high-quality results in your production process.

Another crucial aspect is the lamp's output power and coverage area. Depending on the size of the parts or surfaces you'll be curing, you need to assess the lamp's intensity and the area it can effectively cover. A high-output lamp may be necessary for larger applications to guarantee uniform curing without overexposing certain areas.

Additionally, consider the lamp's design and features such as adjustable settings and ease of use, as these can greatly impact workflow efficiency. Ensure that the flood lamp you choose aligns with your operational needs and contributes to achieving your business goals.

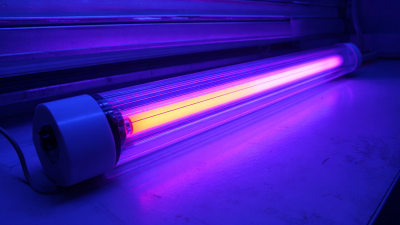

When considering the different UV lamp technologies, a comparative analysis reveals key distinctions that can significantly impact their performance in various applications. Recent studies demonstrate the efficacy of UV LEDs compared to traditional low-pressure UV lamps, particularly in wastewater treatment. For instance, UV-LED systems operating at 280 nm were found to outperform their 254 nm counterparts in community wastewater disinfection, highlighting the advancements in UV technology that enhance microbial inactivation.

Moreover, the integration of UV technology with other processes such as advanced oxidation has shown promising results in degrading pharmaceutical contaminants. Research comparing UV/chlorine and UV-LED/chlorine processes indicates that the latter offers a more efficient degradation rate under specific pH conditions. This ability to synergistically enhance degradation performance can be crucial for businesses focused on environmental compliance and sustainability. Collectively, these comparative insights into UV lamp technologies emphasize the importance of selecting the right system tailored to specific operational needs and desired outcomes.

When selecting a UV curing flood lamp, understanding the relationship between wavelengths and curing performance is crucial. Different wavelengths serve distinct purposes in the curing process; commonly, UV-A, UV-B, and UV-C are utilized in various applications. For instance, UV-A (320-400 nm) is widely recognized for its effectiveness in drying inks and coatings quickly, achieving optimal adhesion and durability. A report by the UV & EB Technology Association notes that using the right wavelength can enhance curing speed by up to 30%, increasing production efficiency.

Tips: When evaluating the wavelength for your specific needs, consider the materials you will be curing. For printers and coaters, UV-A is often preferred, while UV-C (100-280 nm) is more effective in disinfection applications. It is also essential to assess the lamp's intensity at the desired wavelength; higher intensity often translates to better curing performance.

Additionally, businesses should stay informed about the latest advancements in UV technology. According to a market report by Smithers Pira, UV curing systems are expected to grow by 10% annually, driven by the demand for faster curing times and improved energy efficiency. Choosing a UV flood lamp that aligns with these technological advancements can significantly impact your operational efficiency and product quality.

When selecting a UV curing lamp for your business, maintenance and safety considerations should be at the forefront of your decision-making process. Regular upkeep of UV lamps is essential to ensure optimal performance and safety. This includes cleaning the lamp surfaces to maximize UV output and inspecting the bulbs for any signs of wear. A well-maintained lamp not only enhances the quality of the output but also extends the lifespan of the equipment, preventing any interruptions in your service.

Safety is another critical factor when utilizing UV curing technology. With increasing reports linking UV exposure to potential health risks such as skin cancer and allergic reactions, it is crucial to take precautions. Ensure your workspace is equipped with protective barriers and that clients are advised to use protective gear, such as gloves and sunscreen, to minimize exposure. Additionally, it's important to stay informed about the latest studies concerning the risks associated with UV lamps, enabling you to make educated choices for both your business and your clients' well-being.

This chart compares the intensity and energy consumption of different UV curing flood lamps. The data reflects typical values for UV curing lamps used in various industries.