Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

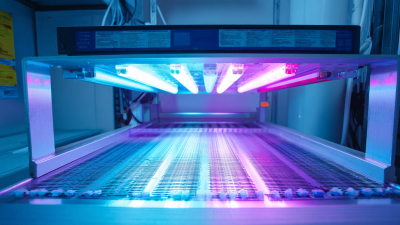

In recent years, the demand for efficient and innovative technologies in industrial processes has led to the rising prominence of UV LED curing lamps. These advanced lighting solutions offer a range of benefits, including faster curing times, greater energy efficiency, and lower environmental impact compared to traditional curing methods. As businesses strive to enhance their production capabilities, exploring alternative types of UV LED curing lamp applications has become essential for achieving operational excellence.

This blog will delve into various innovative approaches for implementing UV LED curing lamps, highlighting their versatility across different industries such as printing, coatings, and adhesives. By examining these alternatives, we aim to provide insights into how businesses can leverage UV LED curing lamps to optimize their processes and meet the growing demand for high-quality, sustainable solutions.

UV LED curing technology has rapidly gained traction in various industries, offering significant advantages over traditional curing methods. At its core, UV LED curing utilizes ultraviolet light emitted from LEDs to initiate photochemical reactions that harden coatings, inks, and adhesives. This process not only enhances the efficiency of production lines but also minimizes energy consumption. According to a market research report by Smithers Pira, the UV LED curing market is projected to reach $1.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 27% from 2021.

Delving into the mechanics, UV LED curing systems produce little to no heat compared to conventional mercury-based lamps, which can warp substrates or compromise product quality. This thermal management allows manufacturers to use more sensitive materials without degradation. Moreover, the instant-on capability of UV LEDs enables rapid curing cycles, reducing downtime and increasing productivity. A study from the RadTech organization reported that companies implementing UV LED technology achieved a 30% increase in production speed while reducing operational costs by up to 50%. Such innovations underscore the transformative potential of UV LED curing technology in modern manufacturing processes, ensuring a competitive edge in the market.

| Parameter | Value | Unit | Notes |

|---|---|---|---|

| Wavelength | 365 | nm | Commonly used for adhesives |

| Lamp Life | 25,000 | hours | Long lifespan compared to traditional curing lamps |

| Curing Speed | 1-10 | m/min | Varies based on materials |

| Power Consumption | 200 | W | Efficient energy usage |

| Irradiance | 1000 | mW/cm² | Determines curing efficiency |

| Heat Output | Low | - | Minimizes heat-related issues |

The integration of UV LED curing technology has significantly transformed various industries, providing numerous benefits over traditional curing methods. According to a report by Smithers Pira, the global UV curing market is projected to reach $4 billion by 2025, driven by the growing adoption of UV LED lamps in applications like printing, coatings, and adhesives. One of the key benefits of UV LED curing is its energy efficiency; these lamps consume up to 80% less power compared to conventional UV lamps, making them an eco-friendly option that reduces operational costs.

In the automotive and furniture industries, for instance, UV LED curing enhances productivity by offering faster curing times, which can range from seconds to minutes. This rapid curing not only accelerates production cycles but also ensures higher quality finishes without the harmful emissions associated with solvent-based systems. Furthermore, research conducted by the RadTech organization indicates that UV LED technology can increase the lifespan of curing equipment, as it operates at lower temperatures, reducing the risk of heat-related damage to substrates. Such advantages make UV LED curing an essential innovation in today's manufacturing processes, paving the way for sustainable industrial practices.

In the automotive and furniture industries, for instance, UV LED curing enhances productivity by offering faster curing times, which can range from seconds to minutes. This rapid curing not only accelerates production cycles but also ensures higher quality finishes without the harmful emissions associated with solvent-based systems. Furthermore, research conducted by the RadTech organization indicates that UV LED technology can increase the lifespan of curing equipment, as it operates at lower temperatures, reducing the risk of heat-related damage to substrates. Such advantages make UV LED curing an essential innovation in today's manufacturing processes, paving the way for sustainable industrial practices.

The quest for optimizing the efficiency of UV LED curing lamps is crucial in various industrial applications, especially in printing and coatings. One innovative technique involves the careful selection of LED wavelengths. By tuning the output to match the specific absorption characteristics of the curing material, manufacturers can significantly improve polymerization rates, leading to faster curing times and reduced energy consumption. This targeted approach not only enhances performance but also minimizes waste, offering a more sustainable solution.

Another effective strategy is the implementation of advanced cooling systems. UV LED lamps generate heat during operation, which can adversely affect efficiency and longevity. Employing optimal thermal management technologies, such as heat sinks or liquid cooling, can maintain ideal operating temperatures. This not only extends the lifespan of the LEDs but also ensures consistent output, further boosting the overall efficiency of curing processes. By integrating these innovative techniques, industries can harness the full potential of UV LED technology, driving both productivity and sustainability.

The adoption of UV LED curing lamps has rapidly increased in various industries due to their energy efficiency and low heat generation. However, challenges still persist in optimizing their performance for specific applications. One common issue is the inconsistency in curing depth, which can lead to uneven finishes. To address this, it's essential to calibrate the exposure time and distance from the UV source, ensuring uniform energy distribution.

Another challenge is the limited range of materials that can be cured effectively with UV LEDs. Certain substrates may require specific wavelengths for optimal curing. Implementing a dual-wavelength system could be beneficial, allowing flexibility in material compatibility.

Tip: Always conduct preliminary tests with different materials to determine the best settings for your specific application. This trial-and-error approach will not only save time but also improve overall efficiency.

Moreover, maintaining the longevity of UV LED lamps can be daunting. Regular maintenance, including cleaning the lenses and monitoring the intensity levels, is crucial for consistent performance.

Tip: Establish a routine maintenance schedule to extend the life of your UV lamps and maximize their curing capabilities.

Maintaining and upgrading UV LED curing systems is essential for maximizing their performance and longevity. One of the best practices is to routinely inspect and clean the UV LED lamps. Dust and debris can significantly affect the efficiency of light output. Regular maintenance should include using a soft, lint-free cloth to gently wipe the lamp surface and surrounding areas, ensuring optimal curing results.

Temperature management is another key factor. UV LEDs are sensitive to heat, which can degrade performance over time. Implementing an effective cooling system, such as fans or heat sinks, can help maintain the ideal operating temperature. Additionally, consider upgrading to more efficient cooling solutions as part of your system's enhancement.

Finally, keep an eye on the power supply and control systems. Upgrading to a more advanced control unit can provide better regulation of power levels, which enhances curing consistency. Implementing a schedule for periodic software updates can also improve system functionality over time, ensuring that your UV LED curing system remains at the forefront of technology.