Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

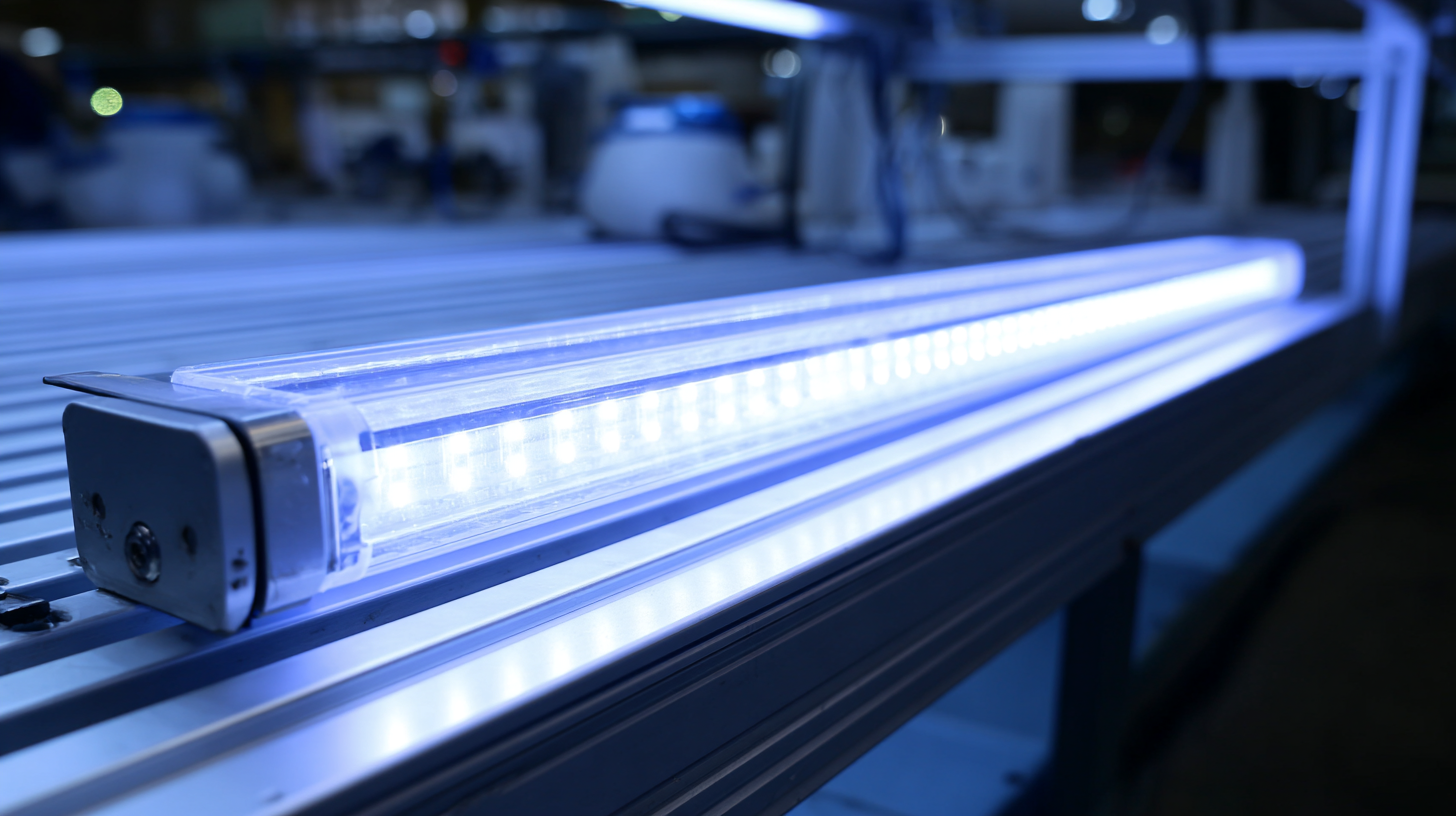

In today's rapidly evolving industrial landscape, the adoption of advanced technologies is paramount for improving efficiency and product quality. One such technology that has gained traction across various sectors is LED curing lamps. According to a report by MarketsandMarkets, the global LED curing equipment market is projected to reach USD 1.2 billion by 2025, growing at a CAGR of 16.2% from 2020 to 2025. This remarkable growth highlights the increasing reliance on LED curing lamps, which offer benefits such as faster curing times, reduced energy consumption, and lower heat generation compared to traditional curing methods. As industries strive to enhance their operational capabilities while adhering to environmental regulations, LED curing lamps emerge as essential tools in optimizing manufacturing processes, thereby positioning themselves at the forefront of modern innovation.

The evolution of curing technology has seen remarkable advancements, particularly with the rise of LED curing lamps. These lamps have emerged as vital tools for modern industries, offering faster processing times and enhanced energy efficiency. Unlike traditional curing methods that rely heavily on ultraviolet light, LED technology utilizes specific wavelengths tailored for various applications, resulting in superior performance, especially in industrial manufacturing and healthcare sectors.

Significantly, the demand for LED curing systems continues to grow, with market forecasts predicting substantial increases driven by their eco-friendly benefits and cost-effectiveness. As industries look to optimize production processes, LED curing lamps not only improve product quality but also reduce waste, positioning themselves as the preferred choice for many applications.

This shift reflects an overarching trend towards more sustainable and innovative manufacturing technologies, further solidifying LEDs' leading role in the future of curing solutions.

LED curing lamps are increasingly becoming essential in modern industries, particularly due to their efficiency and effectiveness in various applications. One of the most significant benefits of LED curing lamps lies in their rapid curing capabilities. By utilizing specific wavelengths of light, these lamps can expedite the drying process for inks, coatings, and adhesives, which is critical in high-speed production environments. This effectiveness not only enhances productivity but also reduces energy consumption, aligning with the industry's move towards more sustainable practices.

Moreover, the versatility of LED curing technology makes it applicable in diverse sectors, including the automotive, electronics, and printing industries. As detailed in recent analyses of the UV LED market, the growing adoption of LED curing systems is driven by their capacity to produce high-quality finishes, minimize waste, and lower operational costs. These advantages contribute to meeting the increasing demand for advanced manufacturing techniques that prioritize efficiency and environmental sustainability, showcasing LED curing lamps as indispensable tools for contemporary industrial operations.

When evaluating curing methods, LED curing lamps show significant advantages over traditional approaches. Traditional curing methods, such as UV lamps or thermal curing, often produce high levels of heat, which can compromise sensitive materials or substrates. In contrast, LED curing operates at much lower temperatures, allowing for precise curing without damaging the integrity of the product. This thermal efficiency not only enhances product quality but also broadens the range of materials that can be effectively cured.

Moreover, the curing speed offered by LED technology is a game-changer for modern industries. While traditional methods can be time-consuming, LED curing provides rapid polymerization, significantly reducing production times. This heightened efficiency translates into increased throughput and lower operational costs. Additionally, LED lamps offer a longer lifespan and lower energy consumption compared to their traditional counterparts, making them a more sustainable choice for businesses looking to minimize their environmental impact while maintaining productivity. The stark contrasts in performance, efficiency, and longevity firmly position LED curing as the preferred method for contemporary industrial applications.

| Parameter | LED Curing Lamps | Traditional Methods |

|---|---|---|

| Curing Speed | Fast (seconds) | Moderate (minutes) |

| Energy Efficiency | High (up to 80%) | Low (40-60%) |

| Heat Generation | Minimal | High |

| Lifespan | Long (up to 20,000 hours) | Short (1,000 - 2,000 hours) |

| Initial Cost | Moderate | Low |

| Maintenance Needs | Low | High |

| Environmental Impact | Low (no mercury) | Moderate (mercury waste) |

When selecting the best LED curing lamp for your industry needs, several factors come into play. First and foremost, understanding the specific curing requirements of your materials is crucial. Different industries, such as automotive, dental, and graphic arts, have varying resin types and thicknesses that require tailored curing solutions. An ideal LED curing lamp should provide the appropriate wavelength to effectively cure the materials, ensuring optimal hardness and durability.

Furthermore, consider the lamp's power output and efficiency. High-power LED curing lamps can significantly reduce curing times, increasing productivity in an industrial setting. Additionally, look for models with adjustable settings; the ability to customize intensity can enhance the versatility of the lamp and accommodate a wider range of applications. Ergonomics and user-friendliness should also be taken into account, as operators must efficiently manage the equipment during use. Ultimately, investing in the right LED curing lamp can lead to improved process efficiency and product quality across various industries.

The evolution of LED curing technology is reshaping modern industries, driving a shift towards faster, more efficient production processes. One of the most significant trends is the integration of this technology into automated manufacturing systems. As industries strive for maximum efficiency, LED curing lamps are being paired with robotics and AI, enabling precise, high-speed applications that save time and reduce waste. This synergy not only enhances productivity but also ensures consistency in curing results, which is essential for industries such as automotive, aerospace, and electronics.

Another noteworthy trend is the ongoing advancements in LED wavelength specificity and intensity control. By developing lamps that offer customizable curing capabilities, manufacturers can adapt the technology to various substrates and coatings, allowing for more versatile applications. Additionally, as sustainability becomes a priority, LED curing is gaining traction due to its energy efficiency and reduced heat output, making it a more eco-friendly option. The combination of these advancements positions LED curing technology as not only essential for current industrial practices but also a cornerstone for future innovations in manufacturing processes.