Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

As the demand for efficient and versatile curing solutions grows across various industries, the UV curing flood lamp has emerged as a crucial tool in manufacturing and finishing processes. According to a recent market research report by ResearchAndMarkets.com, the global UV curing systems market is projected to reach $3.8 billion by 2026, demonstrating an impressive CAGR of 11.5% from 2021. This rapid growth highlights the importance of selecting the right UV curing flood lamp to optimize production, enhance product quality, and reduce energy consumption. Buyers, whether for industrial or creative applications, must navigate a myriad of options and technical specifications to make the best choice. In this blog, we present seven essential tips for global buyers to consider when selecting the optimal UV curing flood lamp for their specific needs, ensuring that they invest wisely in this critical technology.

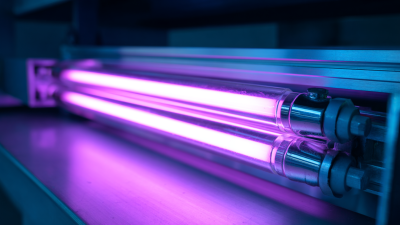

Understanding UV curing flood lamps is crucial for any business aiming to streamline their production processes. These lamps utilize ultraviolet light to cure inks, coatings, and adhesives, resulting in rapid drying and enhanced durability. The technology behind UV curing offers significant advantages over traditional drying methods, such as increased efficiency, reduced energy consumption, and minimized waste. As companies seek to improve their workflows and output quality, choosing the right UV curing flood lamp becomes a pivotal decision.

When selecting a UV curing flood lamp, buyers should consider factors such as lamp intensity, wavelength specificity, and the type of materials they are working with. Different applications may require varying wavelengths to achieve optimal curing results. Furthermore, understanding the relationship between the lamp's performance and the production environment can lead to better integration into existing systems. By prioritizing these aspects, buyers can enhance their production capabilities and pave the way for superior product quality and faster turnaround times.

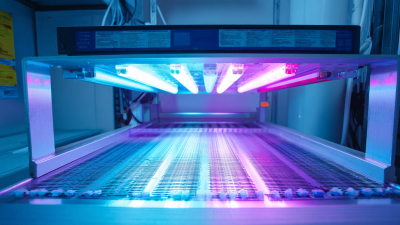

UV curing technology has revolutionized the manufacturing and printing industries, offering significant advantages that maximize productivity. According to a report by Smithers Pira, the global UV curing market reached a value of $4.1 billion in 2020, with projections indicating continued growth as businesses recognize the benefits of this efficient curing method. One of the primary advantages of UV curing is its rapid process—curing can occur in seconds, allowing for shorter production times and increased output.

When selecting a UV curing flood lamp, buyers should consider the wavelength and intensity of the UV light. High-intensity lamps can cure coatings more thoroughly and quickly, reducing bottlenecks in production. Additionally, ensuring compatibility with various substrates, such as plastics, paper, and metals, is crucial for maximizing versatility in applications.

Another essential tip is to evaluate the energy efficiency of the UV lamp. Many modern UV curing systems consume less power than traditional curing methods, which not only lowers operational costs but also aligns with environmentally responsible practices. With UV curing technology evolving rapidly, investing in the right equipment can yield remarkable returns in productivity and sustainability for global buyers.

This chart illustrates the key factors considered by global buyers when selecting UV curing flood lamps, highlighting the importance of various performance metrics.

When selecting the right UV curing flood lamp, compatibility with the materials being processed must be a top priority. It is essential to evaluate how well the lamp’s wavelength aligns with the absorption spectra of the materials. For instance, studies have shown that tuning the UV wavelength can significantly enhance the curing efficiency of resins, leading to better mechanical properties. According to research, using a UV lamp with a spectral output that matches the material's absorption peaks can increase the curing speed by up to 30%, translating to improved production efficiency.

In addition, brands leveraging advanced techniques in material compatibility, akin to those used in studies on polymer blends or natural fiber composites, can significantly enhance product performance. For example, a comprehensive review noted that compatibility assessments involving biopolymers lead to expert recommendations for optimizing formulations in various applications.

Ensuring that your chosen lamp maintains stability amid complex material interactions—and adhering to best practices observed in stability studies—can not only safeguard operational integrity but also ensure superior end-product quality.

When selecting a UV curing flood lamp, energy efficiency and long-term cost savings are critical factors for global buyers. Recent data indicates that state-of-the-art UV curing systems can achieve an impressive 80% reduction in power usage compared to traditional UV technologies, and a 40% reduction when stacked against infrared units. Such significant energy savings not only contribute positively to operational budgets but also align with the growing emphasis on sustainable manufacturing practices.

Tip 1: Prioritize energy efficiency in your selection process. Look for UV lamps that boast high output levels and low energy consumption, as this will ensure reduced operational costs over time.

Tip 2: Consider the total cost of ownership, not just the initial purchase price. Investing in energy-efficient technologies can lead to substantial savings in the long term, as highlighted by studies focusing on various industries. Incorporating advanced UV curing systems can enhance overall production efficiency while ensuring compliance with increasing sustainability standards.

In addition to the direct benefits, choosing the right UV curing flood lamp plays a pivotal role in enhancing the sustainability profile of your manufacturing processes, making it a wise investment for the future.

When selecting the right UV curing flood lamp, safety considerations should be paramount. UV radiation can pose significant health risks, especially with prolonged exposure. According to the International Commission on Non-Ionizing Radiation Protection, UV radiation is linked to skin damage and eye injuries, making it crucial for buyers to prioritize safety features. Look for lamps equipped with protective housings and safety interlocks that prevent accidental exposure. Additionally, incorporating UV protective eyewear and skin coverings in the work environment can greatly reduce health risks.

Tip 1: Always check the UV radiation output and ensure that it complies with the safety standards set by regulatory bodies, such as the American National Standards Institute (ANSI).

Tip 2: When setting up your workspace, ensure sufficient ventilation. The use of UV lamps often requires the management of ozone levels, which can be harmful in high concentrations. A well-ventilated area minimizes ozone buildup and enhances overall safety.

By adhering to these essential safety measures, global buyers can ensure a secure working environment while utilizing UV curing flood lamps effectively.