Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of UV curing technology, proper utilization is essential. As Dr. Emily Hart, a leading expert in Uv Drying Light applications, states, “Understanding the nuances of UV light is crucial for achieving the best results.” Her insight encapsulates the importance of mastering this technique.

When using a Uv Drying Light, small details can significantly impact outcomes. The distance between the light and the material matters. Too far, and the effect diminishes. Too close can lead to overheating or distortion. Many overlook the curing time, which can vary by material type.

Additionally, it's essential to monitor the environment. Humidity and temperature play roles in drying efficiency. An imperfect knowledge of these factors may lead to unsatisfactory results. Engaging with the Uv Drying Light process means embracing a mindset of trial and error. Every session holds lessons that refine the technique.

When it comes to UV drying, understanding the types of UV light is crucial. Two main types are commonly used: UVA and UVB. UVA light is often used for curing coatings. It penetrates deeper and creates strong bonds in resin materials. On the other hand, UVB light is effective for sterilization and can be intense. Its shorter wavelengths can damage surfaces if not used carefully.

Applications vary vastly. For craftsmen, UVA lights are ideal for acrylics and varnishes. Artists often use them for quick drying of inks. In industries, UV curing helps in producing durable finishes. However, improper usage can lead to uneven results. Too much exposure may cause yellowing in some materials.

Reflection is necessary in the application process. Adjusting the distance from the light source can dramatically change outcomes. Over time, users may find their preferred techniques, but experimentation is key. Each piece has its quirks. Not every project will go perfectly the first time. It's essential to learn from each attempt to achieve the desired results.

Understanding the UV light spectrum is crucial for effective UV drying. There are three main types: UVA, UVB, and UVC. Each type has distinct properties and applications. UVA makes up about 95% of UV radiation that reaches the Earth. It penetrates deep into the skin and is primarily responsible for aging. UVB, on the other hand, is responsible for causing sunburn. It only makes up about 5% of UV rays, but it can still be intense. Lastly, UVC is mostly absorbed by the ozone layer, so it does not reach our skin.

In the context of UV drying, understanding these differences is essential. UV curing processes often utilize UVA light. This light triggers photoinitiators in coatings, leading to a rapid chemical reaction. According to a study by the UV and EB Curing Technology Association, UV curing can reduce drying time by up to 80%. However, it's vital to consider the adequate spectrum for specific materials. Incorrect usage may lead to incomplete curing, which can cause chipping or peeling.

Many in the industry fail to grasp the nuances of UV light. Miscalculations in exposure time and spectrum can lead to poor results. Seeking precise wavelengths for applications is essential. A lack of understanding might lead to wastage of materials and time. Balancing performance with quality requires continuous reflection and improvement.

| UV Light Type | Wavelength (nm) | Applications | Safety Notes |

|---|---|---|---|

| UVA | 320 - 400 | Curing inks, dental materials | Less harmful, but prolonged exposure can cause skin aging |

| UVB | 280 - 320 | Skin tanning, phototherapy | Can cause sunburn; protective gear recommended |

| UVC | 100 - 280 | Disinfection, sterilization | Most harmful; proper shielding required |

When it comes to UV drying, optimal distance and positioning are crucial for effective results. The distance of the UV light source from the material can greatly influence curing efficiency. Research indicates that maintaining a distance of about 6 to 12 inches can yield the best outcomes. However, this range may vary depending on the specific application and light intensity.

Positioning also plays a significant role. For even drying, the light should be perpendicular to the surface. Uneven angles can lead to patchy curing, which is often a source of frustration. A study by the Association of UV-Curable Coatings notes that uneven exposure can decrease adhesion by up to 50%. This data highlights the importance of careful positioning during the curing process.

Practitioners often overlook the impact of ambient temperature and humidity on drying. High humidity can extend curing times, while low temperatures can hinder the process. An effective practice is to monitor these environmental factors closely. Achieving optimal conditions may require adjustments and experimentation, which adds to the complexity. Finding the right balance in distance and positioning is essential for maximizing the effectiveness of UV drying.

This chart illustrates the curing efficiency of UV drying lights at various distances. As the distance from the UV light increases, the efficiency of curing decreases significantly. It is essential to find the optimal distance for effective UV drying results.

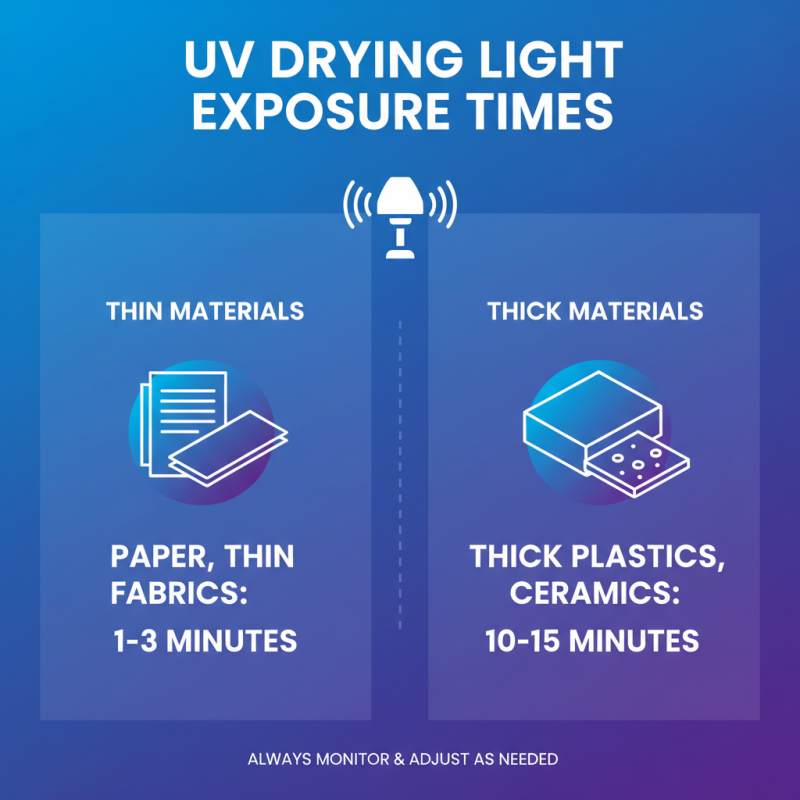

When working with UV drying lights, knowing the right exposure times is crucial. Different materials and thicknesses respond uniquely to UV light. For instance, thinner materials like paper require less time—often just one to three minutes. Conversely, thick plastics may demand longer exposure, around ten to fifteen minutes. These times are estimates; monitoring is essential.

Using a UV light often leads to experimentation. You might find that some plastics become too brittle under extended exposure. On the other hand, some inks may not cure properly if exposed too briefly. This variability can be frustrating. You may need to run tests to determine optimal results. Adjust your times based on specific projects.

Remember, environmental factors can also play a role. Distance from the light can alter effectiveness. If the light source is too far away, it might not cure well. If it's too close, it risks overheating the material. Keep these elements in mind. Refining your process can lead to better outcomes.

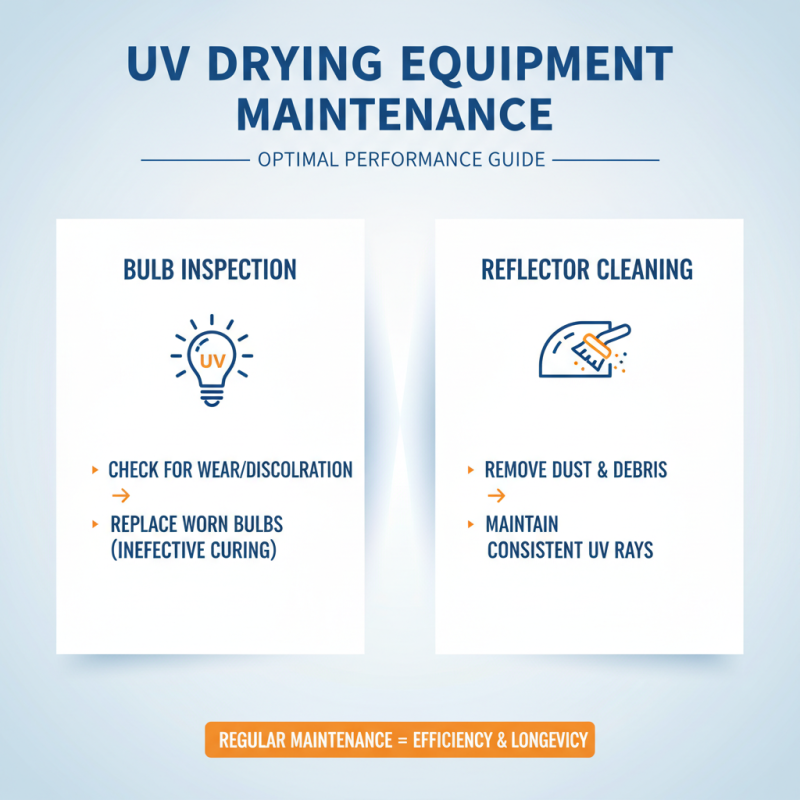

Proper maintenance of UV drying equipment is crucial for optimal performance. Start with regular inspections of bulbs. Check for any signs of wear or discoloration. A worn bulb can lead to ineffective curing. Also, ensure that the reflectors remain clean. Dust and debris can block UV rays, reducing efficiency. Regular cleaning will help maintain consistent results.

Humidity and temperature can affect equipment performance. Monitor these environmental factors. Extreme conditions may lead to inconsistent curing results. Furthermore, maintain proper distance settings between the UV source and the material. If the distance is too great, the UV rays lose intensity. It is worth it to adjust settings frequently based on material type.

Recordkeeping can be quite useful. Track maintenance schedules and any changes in performance. If results vary, revisit past logs for clues. Ignoring small issues can lead to bigger problems later. Reflecting on past performance helps identify patterns that may need adjustment. Consistent attention and corrections can greatly enhance your UV drying results.