Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

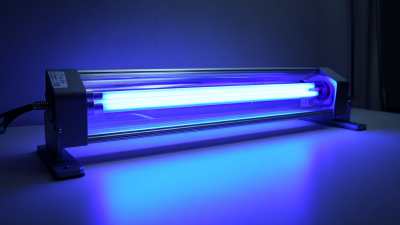

The landscape of manufacturing and technology is on the brink of a significant transformation, driven by innovative advancements in the field of Uv Curing Light Source. As industries seek faster, more efficient, and environmentally friendly methods for curing materials, Uv curing technology is emerging as a game-changer. This blog delves into the future of Uv Curing Light Source innovations, exploring the myriad applications across various sectors, from automotive to electronics to medical devices. The enhanced efficiency and energy-saving capabilities of these light sources not only promote sustainability but also open the door for new possibilities in product development and quality improvement. In this context, we will discuss several compelling reasons why Uv curing technology is rapidly becoming indispensable, highlighting the important role it plays in shaping the future of manufacturing processes.

Emerging technologies in UV curing light sources are paving the way for innovative applications across various industries. With advancements in LED technology, UV lights are becoming smaller, more efficient, and capable of delivering higher intensity output. This transition not only enhances curing speed but also reduces energy consumption, making UV curing an eco-friendlier option. Additionally, the development of broad-spectrum UV LEDs allows for more versatile applications, including in the printing, adhesive bonding, and coatings sectors.

Tip: When choosing UV curing systems, consider ones that offer adjustable wavelengths. This flexibility can significantly increase the range of materials you can work with, improving the overall effectiveness of your projects.

Moreover, as the demand for sustainable manufacturing practices increases, there is a growing focus on UV curing's role in minimizing waste and emissions. Innovations such as efficient power management and integrated sensors for curing optimization can provide precise control over the curing process, ensuring consistency and quality in the final products.

Tip: Stay updated with the latest innovations by attending trade shows and webinars. Engaging with industry experts will give you insights into new technologies and best practices that can elevate your UV curing operations.

The UV curing industry is witnessing significant growth, primarily driven by its diverse applications across various sectors. The global UV curing market is projected to reach approximately $4.9 billion by 2026, according to a report by MarketsandMarkets. This surge is largely attributed to the increasing demand for eco-friendly and energy-efficient curing technologies in industries such as automotive, electronics, and packaging. UV curing technologies eliminate the need for solvents, thereby reducing volatile organic compounds (VOCs) and enhancing workplace safety.

In automotive manufacturing, UV curing is utilized for coatings that offer enhanced durability and resistance to scratches and chemicals. The coatings not only improve the aesthetic appeal of vehicles but also contribute to their longevity, reducing the need for frequent repainting. Similarly, in the packaging industry, UV-cured inks and coatings ensure faster production speeds while maintaining high-quality graphics, offering a competitive edge. By leveraging UV curing technologies, companies can achieve rapid production cycles without sacrificing quality, thus meeting the growing consumer demand for faster delivery times.

The latest innovations in UV curing technology have led to significant advancements in efficiency and application versatility, transforming industries ranging from printing to coatings. According to a recent report from MarketsandMarkets, the global UV curing market is projected to reach USD 5.57 billion by 2026, growing at a CAGR of 10.9% from 2021. This growth is primarily driven by the increasing demand for environmentally friendly and energy-efficient curing solutions. New LED UV curing systems, for example, offer a reduced energy consumption of up to 50% compared to traditional mercury lamps, allowing businesses to lower operational costs while minimizing their environmental footprint.

Moreover, the advancements in UV curing technology have introduced faster curing times and enhanced adhesion properties. A study by Grand View Research indicates that UV-curable coatings can achieve full cure within seconds, significantly speeding up production cycles. This rapid curing capability not only improves throughput but also expands application possibilities in sectors such as automotive and electronics. With enhanced efficiency and performance, the latest UV curing innovations are positioning themselves as vital components in the manufacturing processes of the future, catering to both productivity goals and sustainability initiatives.

The pursuit of sustainability in UV curing technologies has led to innovative breakthroughs that not only improve efficiency but also reduce environmental impact. As industries increasingly adopt UV LED solutions, the transition from traditional light sources to eco-friendly alternatives is gaining momentum. UV LEDs, being more energy-efficient and having a longer lifespan, contribute to lowering energy consumption and minimizing chemical emissions, aligning with modern sustainability trends.

Furthermore, the application of UV curing in various sectors, including electronics and coatings, underscores its versatility while maintaining a focus on eco-friendliness. Strategies to mitigate the environmental footprint of such technologies are vital, especially as cities expand and air quality becomes a pressing concern. By promoting the use of UV LED technology, industries can significantly cut down on pollutants released into the atmosphere, contributing to cleaner urban environments.

As we look ahead, integrating sustainable practices in UV curing not only fulfills regulatory standards but also meets the growing demand for greener solutions. This commitment to sustainability in light source innovations will undoubtedly shape the future of industrial processes and pave the way for a more eco-conscious approach in manufacturing.

This chart illustrates the growth in the adoption of various eco-friendly UV curing light sources from 2018 to 2023. The focus is on sustainability trends in the UV curing industry, showcasing a shift towards more efficient and environmentally friendly solutions.

Implementing UV curing technology in your business can significantly enhance efficiency and quality, but understanding the best practices is crucial. One key aspect is to ensure that your UV curing equipment is compatible with the specific materials you are using. For instance, choosing the right UV-curable adhesives can maximize bonding strength while minimizing curing time. Each application may have unique challenges, and it’s important to systematically address those to streamline production processes.

Additionally, consider the environmental conditions of your workspace. UV curing requires optimal exposure to light for effective results, so maintaining a controlled environment can also improve output quality. Regular maintenance of curing equipment is equally essential to ensure consistent performance, as even minor issues can lead to significant production delays. By prioritizing these best practices, businesses can better harness the advantages of UV curing technology, leading to more durable products and improved operational efficiency.

Additionally, consider the environmental conditions of your workspace. UV curing requires optimal exposure to light for effective results, so maintaining a controlled environment can also improve output quality. Regular maintenance of curing equipment is equally essential to ensure consistent performance, as even minor issues can lead to significant production delays. By prioritizing these best practices, businesses can better harness the advantages of UV curing technology, leading to more durable products and improved operational efficiency.