Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

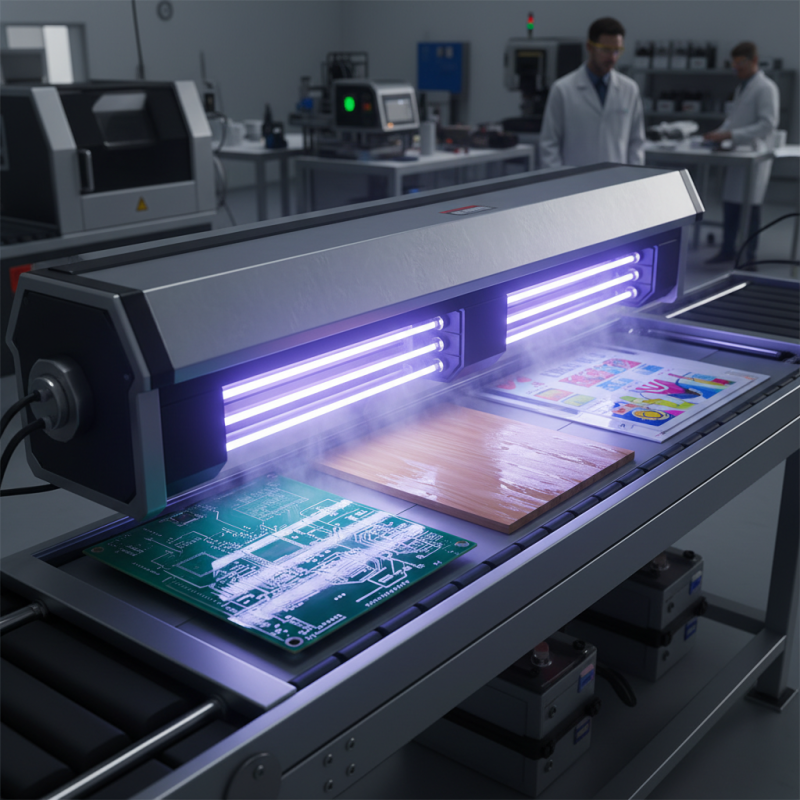

In the realm of modern coatings, finishes, and printing technologies, the use of a UV drying lamp has become essential for achieving rapid and efficient curing. As industries continue to evolve with advancements in materials and applications, the selection of the right UV drying lamp can significantly impact productivity and quality. Whether you're a professional in printing, woodworking, or any surface treatment process, understanding the nuances of UV drying lamps is crucial to meeting your operational needs.

This guide provides a comprehensive overview of the factors to consider when choosing a UV drying lamp tailored to your specific requirements. From wavelength and intensity to lamp types and configurations, we will explore how these elements influence the curing process. By the end of this guide, you'll be equipped with the knowledge to make informed decisions, ensuring that your investment in a UV drying lamp contributes positively to your production workflow and end-product quality.

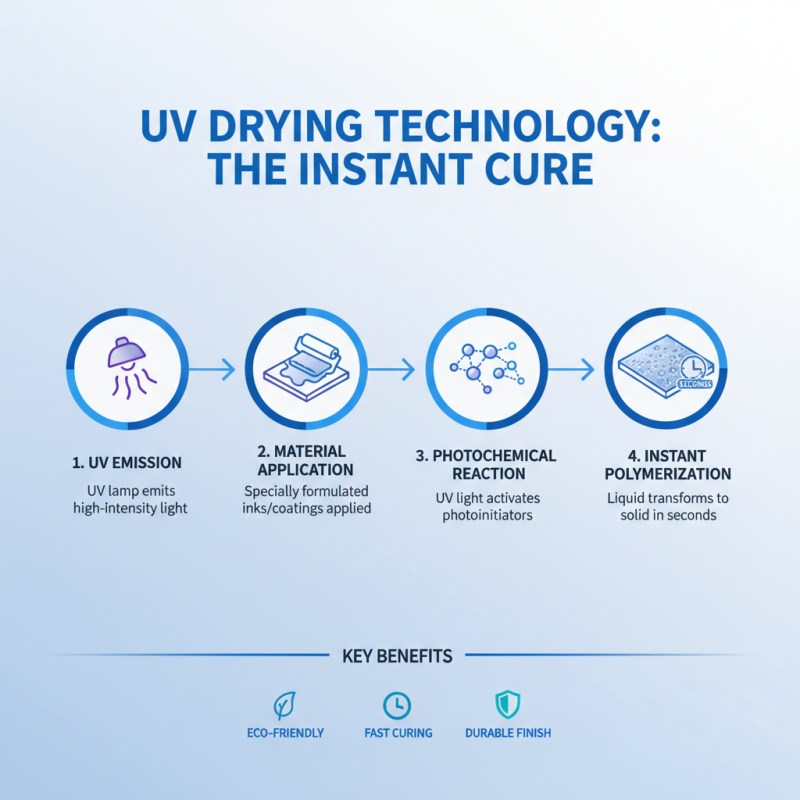

UV drying technology is a revolutionary process that utilizes ultraviolet (UV) light to cure or dry various materials, such as inks, coatings, and adhesives. This method relies on the photochemical reaction initiated when UV light interacts with specially formulated materials, causing them to harden in a matter of seconds. The process begins with the emission of UV rays from a lamp, which triggers a chemical reaction in photoinitiators within the ink or coating, resulting in polymerization—a transformation from a liquid state to a solid form.

Understanding how UV drying works is essential for selecting the right equipment for specific applications. The effectiveness of UV drying is influenced by several factors, including the type of UV light emitted (UVA, UVB, or UVC), the distance between the lamp and the material, and the duration of exposure. Different substrates may require tailored wavelengths and intensities to achieve optimal curing results. Additionally, advancements in UV technology have led to the development of energy-efficient lamps and systems that produce less heat, making the technology increasingly versatile for use in various industrial and commercial processes.

When selecting a UV drying lamp, understanding the various types available is essential for making an informed decision. Broadly, UV drying lamps can be categorized into three main types:

When it comes to selecting a UV drying lamp, there are several key factors to consider that will significantly impact your choice. First, consider the wavelength of the UV light. Different applications may require specific wavelengths to achieve optimal curing times and consistency. For instance, if you're working with certain inks or coatings, their compatibility with the UV light's wavelength is crucial for effective drying.

Another important consideration is the intensity of the UV light. Higher intensity lamps can cure materials more quickly, which is beneficial for high-volume applications. However, it's essential to balance speed with the risk of damaging heat exposure, as excessively high intensity can cause material warping or degradation.

**Tips:** Always check the manufacturer’s specifications for curing times at different intensities to ensure the lamp meets your operational needs. Additionally, consider the lamp's energy efficiency; more efficient options may have a higher upfront cost but can save you money in the long run through reduced energy consumption. Lastly, assess the lamp's size and portability based on your workspace requirements; a flexible, lightweight lamp may be ideal for smaller or mobile operations.

| Feature | Description | Importance |

|---|---|---|

| Wavelength Range | Select a lamp with an optimal wavelength range for your specific curing needs, typically between 250-400 nm. | High |

| Power Output | Consider the power output measured in watts, which affects curing speed and efficiency. | Medium |

| Type of UV Lamp | Different types include mercury vapor, LED, and metal halide, each with its advantages. | High |

| Cooling System | Effective cooling systems help reduce heat damage to materials and prolong lamp life. | High |

| Size and Portability | Depending on your workspace, portable or fixed-size lamps may be necessary. | Medium |

| Safety Features | Look for features such as UV shields, automatic shut-off, and proper reflective housings. | High |

| Cost | Consider your budget while evaluating the cost against the lamp's features and longevity. | Medium |

When selecting the ideal UV drying lamp for your specific application, it's crucial to understand the various specifications and how they align with your operational needs. The industry report from the Global UV Curing Market estimates that the market for UV curing technologies is expected to grow significantly, with a compound annual growth rate (CAGR) of approximately 8.5% through 2027. This growth is driven largely by the increasing demand for high-efficiency drying solutions in printing, coatings, and adhesives, where precision and speed are paramount.

One of the primary specifications to consider is the wavelength of the UV light emitted by the lamp. Different applications, such as graphic arts or wood finishing, require different wavelengths for optimal curing. For instance, a 365nm wavelength is typically effective for photoinitiators used in printing applications, whereas 395nm wavelengths are preferable for coatings and inks that need rapid curing times. According to a report by Smithers Pira, proper matching of these spectral outputs to the materials being cured can improve the adhesion and durability of the finished product, leading to lower defect rates and higher production efficiency.

Additionally, understanding the power output of the UV lamp is essential. Measurements are often expressed in watts per centimeter (W/cm), and higher output lamps can improve throughput and reduce curing times. However, selecting a lamp with an excessively high power output for an application can risk overheating or damaging sensitive substrates. Research indicates that optimizing the balance between power density and exposure time can result in a more effective and efficient curing process, achieving superior results across various materials and applications.

When operating UV drying lamps, proper maintenance is crucial for ensuring optimal functionality and safety. Regular inspections should be conducted to identify any damage to the lamp, power cords, or other components. Keeping the lamp clean from dust and debris will help maintain its efficiency and prolong its lifespan. It's also important to replace the lamps as recommended by the manufacturer, as degraded bulbs can emit less UV light, resulting in ineffective drying and potential damage to the items being treated.

Safety is of utmost importance when using UV drying lamps. Operators should always wear appropriate personal protective equipment, including UV-blocking goggles and gloves, to protect themselves from harmful radiation. Additionally, ensuring proper ventilation in the working area can help mitigate exposure risks. It is essential to follow the operational guidelines provided with the equipment, including keeping a safe distance from the lamp while in operation and never looking directly at the UV light. This combination of regular maintenance and strict adherence to safety protocols will ensure a safe and effective drying process.