Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

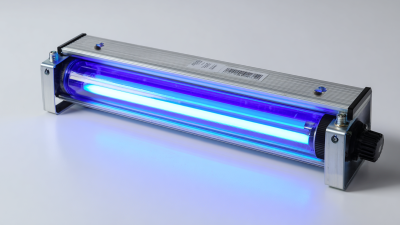

In today's fast-paced work environment, leveraging the right tools is essential for maximizing productivity, and one such innovation making waves is the LED UV curing light. These advanced lighting solutions offer not only efficiency but also precision in various applications, from printing to coatings. By harnessing the power of LED UV curing lights, businesses can significantly reduce curing times, enhance product quality, and lower operational costs. This article will delve into data-driven strategies that optimize the use of LED UV curing lights, providing insights that lead to improved workflow and productivity. As we explore best practices and evidence-based approaches, you'll discover how integrating this technology into your processes can transform your operations and drive success.

LED UV curing lights are revolutionizing productivity across various sectors by streamlining processes and enhancing product quality. One key advantage is their speed; compared to conventional curing methods, LED UV curing allows for instant drying. This means that businesses can significantly reduce turnaround times, which is essential in fast-paced industries such as labels and packaging. As highlighted in recent trends, suppliers are focusing on optimizing products while maintaining sustainability and quality, making LED UV technologies increasingly attractive.

**Tips for Maximizing Productivity with LED UV Curing Lights:**

1. **Invest in Quality Equipment:** High-performance LED UV lamps can provide consistent curing results with minimal maintenance, leading to less downtime and improved production schedules.

2. **Train Your Team:** Ensuring that your staff is well-versed in the latest curing technologies not only boosts efficiency but also reduces the risk of errors, optimizing your production workflow.

3. **Monitor and Adjust Parameters:** Regularly assessing and adjusting curing parameters based on real-time data can enhance productivity levels and ensure that your outputs meet the desired quality standards.

| Dimension | Data |

|---|---|

| Curing Time Reduction | Up to 50% faster compared to traditional curing |

| Energy Efficiency | Uses 70% less energy than conventional UV lamps |

| Heat Generation | Significantly lower heat output, preserving material integrity |

| Lifespan | Over 20,000 hours of operation |

| UV Output | Wavelengths ranging from 365 to 405 nm |

| Return on Investment (ROI) | Average ROI within 6-12 months |

| Environment Impact | Reduced VOC emissions, compliant with green standards |

When selecting LED UV curing lights, several key factors can significantly influence productivity and effectiveness in various applications. One of the primary considerations is the intensity and wavelength of the UV light, as different materials respond optimally to specific wavelengths. Ensuring that the LED UV curing light matches the curing requirements for inks, coatings, or adhesives can enhance adhesion quality and reduce curing times, which directly impacts overall productivity.

Market trends highlight the importance of choosing the right curing technology. For instance, the desktop UV curing machine market was valued at $0.68 billion in 2022, with projections to reach $1.15 billion by 2030. This growth reflects a compound annual growth rate (CAGR) of 7.0% from 2024 to 2030, indicating a shift toward efficient curing solutions that meet increasing demand. Additionally, the energy efficiency and lifespan of LED UV curing lights are essential for reducing operational costs and minimizing downtime, further emphasizing the importance of strategic selection based on industry needs. By leveraging data-driven insights, businesses can make informed decisions that enhance their productivity through optimal curing solutions.

In the realm of UV curing processes, leveraging data-driven techniques can significantly enhance efficiency and productivity. By analyzing performance metrics, businesses can identify bottlenecks and optimize their workflows. For instance, tracking curing times and energy consumption allows manufacturers to fine-tune their settings for maximum output.

**Tips:** One effective strategy is to implement regular maintenance schedules for your LED UV curing lights. Keeping equipment in top condition not only extends its lifespan but also ensures consistent performance. Additionally, utilize software tools to monitor real-time data on curing cycles; this can provide insights into operational efficiency and highlight areas for improvement.

Another technique involves experimenting with different light intensities and curing durations based on substrate types. Data analytics can guide these experiments, helping determine the best settings for each application. This tailored approach not only speeds up production but also improves the quality of the end product. By harnessing data effectively, companies can transform their UV curing processes into a streamlined and productive operation.

This chart illustrates the efficiency of UV curing processes with varying exposure times. Based on empirical data, we can see the correlation between curing time and productivity.

To ensure optimal performance of LED UV curing lights, regular maintenance is crucial. According to a report by the

Adhesive and Sealant Council, proper upkeep can enhance the lifespan of LED UV systems by up to 30%, significantly reducing replacement costs.

This involves routine checks of alignment, protective lens cleaning, and verifying the intensity of the UV output. Ensuring that lights are free from dust and debris can prevent overheating and maintain consistency in curing processes.

Additionally, monitoring the environment where LED UV curing units are operated is essential. A study published in the

Journal of Applied Polymers highlights that ambient temperatures and humidity can affect curing efficiency. Keeping the curing equipment in a controlled environment not only improves product quality but also maximizes energy efficiency.

By implementing a scheduled maintenance routine and adhering to environmental factors, businesses can achieve peak productivity while extending the operational life of their LED UV curing lights.

In recent years, industries such as printing, coatings, and adhesives have turned to LED UV curing lights to enhance productivity significantly. A notable case study involves a commercial printing company that transitioned from traditional drying methods to LED UV curing technology. This shift not only reduced the curing time from several minutes to mere seconds, but it also increased the overall throughput of printed materials. As a result, the company was able to take on more projects, leading to a 30% increase in revenue within the first year of implementation.

Another compelling example comes from a manufacturer of adhesives who incorporated LED UV curing into their production line. By leveraging this technology, they observed a dramatic improvement in production efficiency, cutting down the assembly time for their products. Furthermore, the high precision offered by LED UV curing minimized waste, allowing for better resource utilization. The result was not only an enhanced bottom line but also a strengthened competitive advantage in the market, demonstrating how LED UV curing can be a game changer in various sectors seeking to optimize productivity.

Another compelling example comes from a manufacturer of adhesives who incorporated LED UV curing into their production line. By leveraging this technology, they observed a dramatic improvement in production efficiency, cutting down the assembly time for their products. Furthermore, the high precision offered by LED UV curing minimized waste, allowing for better resource utilization. The result was not only an enhanced bottom line but also a strengthened competitive advantage in the market, demonstrating how LED UV curing can be a game changer in various sectors seeking to optimize productivity.