Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

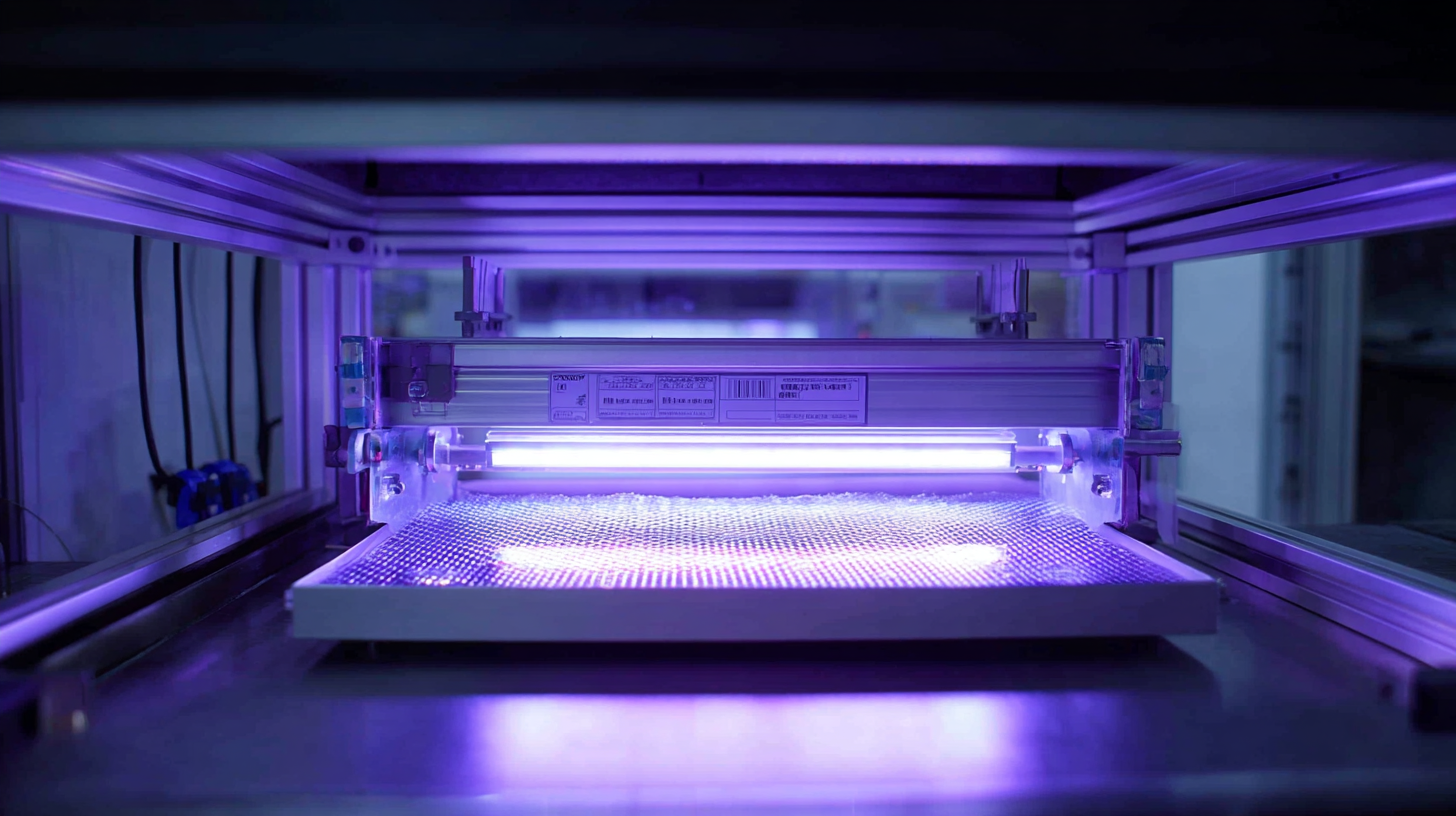

In today's fast-paced industrial landscape, mastering the technology behind UV LED curing lamps has become indispensable for businesses aiming to enhance efficiency and reduce operational costs. According to a report by Smithers Pira, the global market for UV curing is expected to grow significantly, reaching a valuation of over $6 billion by 2026, driven by the rising demand for eco-friendly and energy-efficient solutions. UV LED curing lamps, in particular, are gaining traction due to their superior energy savings and long lifespan compared to traditional UV lamps. This technological shift is not just a trend but a transformative movement that can redefine production processes across various sectors, including printing, coatings, and adhesives. As businesses strive to stay ahead of the curve, understanding the intricacies and advantages of UV LED curing technology becomes crucial for long-term success and sustainability.

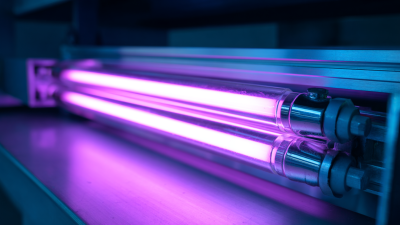

Understanding the technology behind UV LED curing lamps is crucial for businesses looking to enhance their production efficiency and product quality. Unlike conventional UV lamps, which use mercury to emit UV radiation, UV LED lamps rely on solid-state technology. This difference results in several benefits, including reduced energy consumption, longer lifespan, and minimal heat generation. Such advantages translate to lower operational costs and a decreased risk of thermal damage to substrates, making UV LED lamps an appealing choice for various applications, from printing to coatings.

When comparing key features of UV LED curing lamps, factors such as wavelength options, curing speed, and compatibility with different materials become essential. Most UV LED lamps operate at specific wavelengths, typically around 385 nm and 395 nm, which can significantly affect curing performance based on the inks or coatings used. Moreover, the curing speed of these lamps varies, with some models offering instant curing capabilities that can accelerate production times. Understanding these features allows businesses to select the right UV LED curing lamp tailored to their specific needs, ultimately driving business success through improved operational efficiency and product quality.

In recent years, the shift towards UV LED curing solutions has gained momentum, particularly due to their impressive energy efficiency compared to traditional UV curing methods. According to a report by the *North American Printing Ink Association*, UV LED systems can achieve energy savings of up to 80% compared to conventional mercury vapor lamps. This significant reduction in energy consumption not only results in lower operational costs but also aligns with growing sustainability goals within the industry.

Furthermore, the lifespan of UV LED lamps exceeds that of traditional UV lamps by a factor of two to three. A study by *Gartner Research* highlights that while traditional UV lamps last approximately 1,000 hours, UV LED lamps can operate for over 20,000 hours, substantially reducing replacement frequency and maintenance costs. As businesses seek to optimize their operations, the advantages of UV LED curing are increasingly compelling, making it a wise investment for enhancing productivity and profitability.

Moreover, with lower heat output, UV LED curing systems minimize the risk of substrate damage, allowing for a broader range of applications across various industries. As noted in a *2019 report by the UV LED Technology Association*, 75% of businesses that switched to UV LED solutions reported improved quality in prints and coatings, further emphasizing the effectiveness of this technology in modern manufacturing processes.

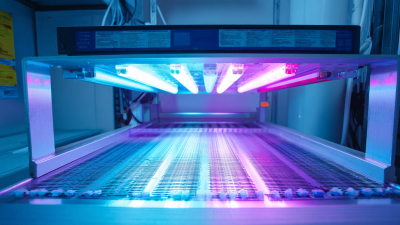

When it comes to mastering UV LED curing lamps, evaluating curing speed is crucial for ensuring optimal performance in your business.

Different lamps are designed with varying wavelengths and intensities, which can influence the speed at which materials cure. For instance, lamps with shorter wavelengths generally provide faster curing times, but they may also result in less depth of cure compared to those with longer wavelengths. Therefore, it’s essential to compare the specifications of different lamps to see how they align with your specific curing needs.

Tip: Always conduct preliminary tests with the UV LED lamps you are considering. This will give you a clearer picture of their performance in real-world applications, allowing you to choose the best fit for your business.

Moreover, don't overlook the importance of the substrate being cured. Different materials react uniquely to UV light, and understanding these interactions can help improve your overall efficiency. An investment in a high-quality UV LED lamp might save you time and money in the long run, but it’s vital to consider how the lamp integrates with your existing workflow.

Tip: Keep a detailed log of your curing times and outcomes with different materials and lamps. This data will be invaluable in optimizing your processes and making informed decisions about future equipment investments.

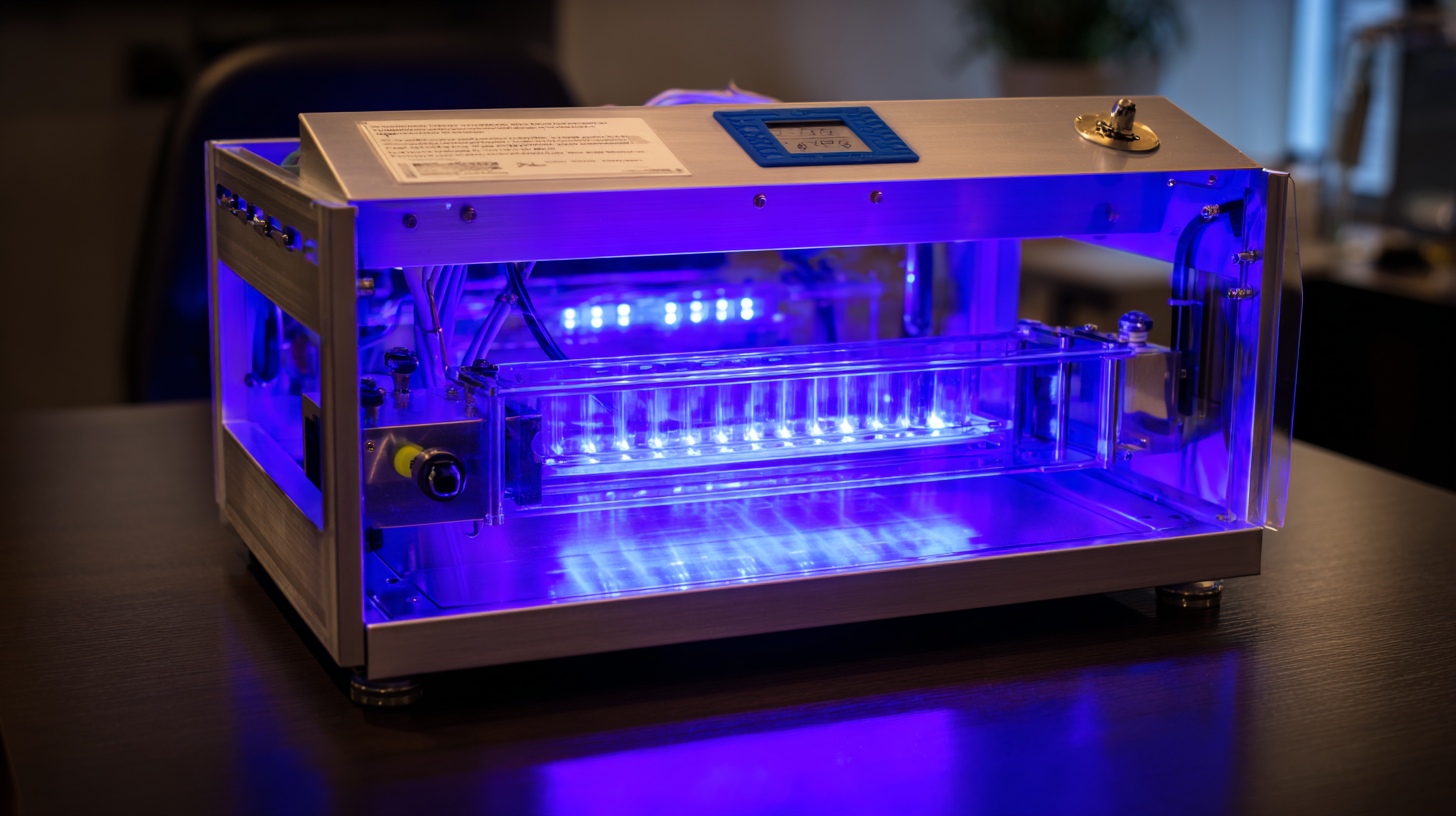

When considering the adoption of UV LED curing systems for your business, a thorough cost analysis is essential. Upfront expenses include the initial investment in high-quality UV LED lamps, curing units, and any necessary installation or training. While these costs can be significant, they are often offset by the impressive long-term savings achieved through reduced energy consumption and lower maintenance requirements. UV LED systems are known for their efficiency and longevity, allowing businesses to minimize operational downtime and maximize productivity.

Moreover, as trends shift towards sustainability, the UV coatings market is witnessing substantial growth driven by the demand for eco-friendly solutions. Investing in UV LED technology not only aligns your business with these emerging eco-conscious strategies but also positions you competitively in a rapidly evolving market. By opting for UV LED curing systems, businesses can enhance their product offerings with advanced, environmentally friendly coatings, ultimately leading to improved customer satisfaction and long-term success.

When integrating UV LED curing technology into your business operations, understanding compliance and safety standards is paramount. Industry reports, such as those from the American Coatings Association, reveal that adherence to these standards can significantly reduce the risk of workplace hazards and enhance overall production quality. For instance, a study indicated that workspaces employing compliant UV LED systems reported a 30% decrease in accidents related to improper curing processes.

Tips: Always ensure your UV LED curing lamps meet the latest safety certifications, such as UL and CE, to protect your workers and product integrity. Regularly review the manufacturer’s guidelines and maintenance requirements to keep your equipment running safely and effectively.

Environmental regulations are another crucial aspect of compliance in UV LED curing. According to a report from the European Chemicals Agency, businesses that utilize UV LED technology can reduce volatile organic compound (VOC) emissions by over 90% compared to traditional curing systems. This not only helps in meeting stringent environmental policies but also boosts your sustainability profile.

Tips: Consider investing in UV LED systems that are designed with energy efficiency in mind; lower energy consumption not only cuts costs but also minimizes your carbon footprint. Regularly train your staff on safety practices and the correct operational procedures for UV technology to maintain a compliant and effective working environment.