Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

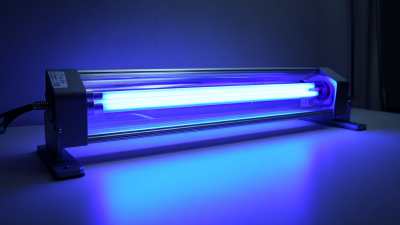

As the demand for advanced printing and coating technologies continues to rise, the spotlight is increasingly cast on innovations in Uv Led Curing Lamp solutions. The market for UV LED curing systems is projected to witness remarkable growth, with a compound annual growth rate (CAGR) of 12.2% from 2020 to 2025, as reported by industry analysts. This surge is driven by the need for environmentally friendly alternatives to conventional curing methods, which are often energy-intensive and harmful to the environment. At the 2025 China Import and Export Fair, the unveiling of cutting-edge Uv Led Curing Lamp technologies promises to revolutionize sectors ranging from packaging to automotive coatings, enhancing efficiency and sustainability. With its long lifespan, lower operating costs, and immediate curing capabilities, the Uv Led Curing Lamp stands at the forefront of this transformation, capturing the attention of manufacturers and consumers alike.

The 2025 China Import and Export Fair has become a significant platform for showcasing cutting-edge technologies, particularly in the realm of UV LED curing. This year, a range of innovative UV LED curing technologies were prominently featured, demonstrating how far this sector has advanced. Among the highlights were energy-efficient curing systems that not only reduce operational costs but also minimize environmental impact. These advancements cater to various industries including printing, coatings, and even health care, enhancing both productivity and sustainability.

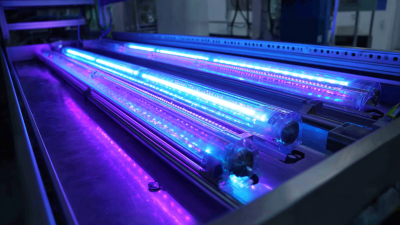

One noteworthy innovation presented at the fair was the application of UV LED curing in rapid prototyping and production processes. These technologies allow manufacturers to achieve faster curing times, leading to shorter production cycles. Exhibitors emphasized the integration of smart technology in UV LED curing lamps, which enables precise control of the curing process through real-time monitoring and adjustment. This level of sophistication not only improves the overall quality of finished products but also positions businesses to respond quickly to market demands, reflecting the industry's shift towards more adaptable and intelligent manufacturing solutions.

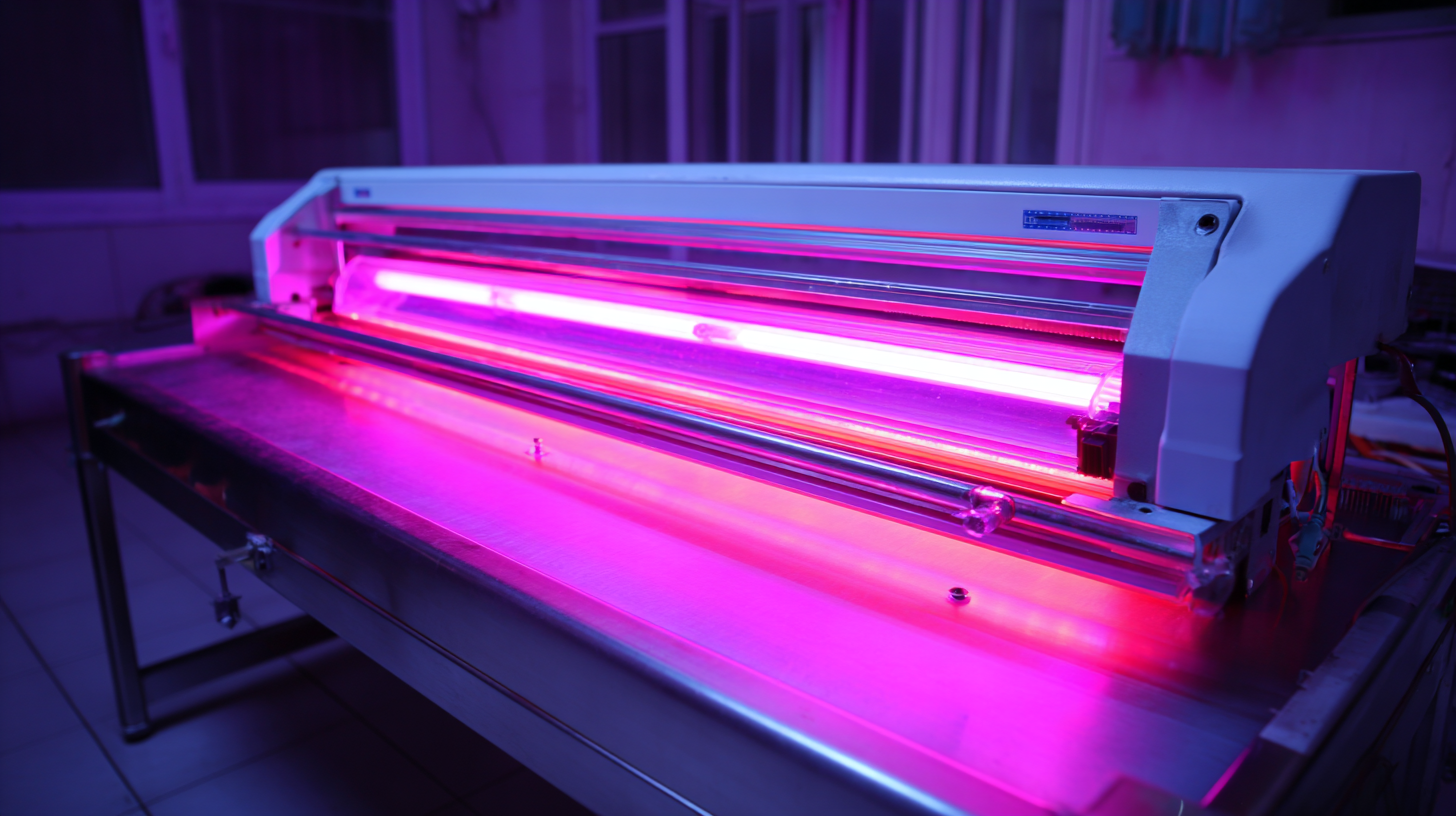

At the 2025 China Import and Export Fair, industry leaders are set to unveil their latest breakthroughs in UV curing solutions, showcasing innovations that promise to transform various manufacturing processes. These advancements are not just incremental improvements; they represent significant leaps forward in efficiency, sustainability, and versatility of UV LED curing lamps. With the push for environmentally friendly technologies, these new solutions aim to reduce energy consumption while enhancing output quality.

Among the key presentations, several companies will highlight their cutting-edge designs that cater to diverse industries, from automotive to electronics. The introduction of smart UV curing systems equipped with IoT capabilities will allow for real-time monitoring and optimization, ensuring that production lines operate at peak efficiency. This intersection of technology and functionality illustrates the ongoing evolution of UV curing processes, positioning industry leaders at the forefront of an exciting new era in manufacturing.

| Innovation Type | Description | Key Benefits | Application Areas | Environmental Impact |

|---|---|---|---|---|

| High-Efficiency UV LEDs | Utilizing advanced semiconductor technology to increase UV output efficiency. | Reduces energy consumption and enhances curing speed. | Industrial printing, coating applications. | Lower carbon footprint compared to traditional curing methods. |

| Smart UV Curing Systems | Integrated sensors for real-time monitoring and optimization of curing processes. | Improves quality control and reduces wasted materials. | Flexible packaging, automotive parts. | Enhances resource efficiency and reduces waste production. |

| Portable UV Curing Devices | Lightweight and battery-operated devices for on-the-go applications. | Increased versatility and accessibility for various industries. | Construction, field repairs. | Reduces energy usage in remote locations. |

| Multi-Wavelength Curing Units | Devices that offer multiple wavelength outputs for diverse material compatibility. | Enhances curing options for various formulations and substrates. | Electronics, medical devices. | Facilitates use of eco-friendly materials. |

| UV Cure Inks & Coatings | Development of specialized inks and coatings optimized for UV curing. | Enhanced durability and quicker drying times. | Graphic arts, plastic manufacturing. | Lower VOC emissions and safer for end-users. |

The evolution of UV LED curing technology is pivotal in enhancing both sustainability and efficiency in various industrial processes.

Unlike traditional curing methods, UV LED lamps operate at lower temperatures and significantly reduce energy consumption.

This shift not only minimizes the carbon footprint associated with the curing process but also extends the lifespan of materials being cured, driving both economic and environmental benefits.

At the 2025 China Import and Export Fair, innovations in UV LED curing lamps are expected to showcase advancements that further optimize efficiency.

These innovations may include improved lamp designs that enhance light penetration and curing speed, leading to shorter processing times and increased productivity.

Additionally, the ability to incorporate eco-friendly materials into UV LED processes aligns with global sustainability goals, demonstrating that environmental responsibility can coexist with industrial growth.

As the 2025 China Import and Export Fair approaches, the spotlight is on the rapid advancements in UV LED curing technologies. These innovations are transforming various industries by enhancing efficiency and reducing energy consumption. The rise of UV LED curing applications in fields such as printing, coating, and adhesive bonding is indicative of a broader trend towards sustainable and environmentally friendly manufacturing processes. The ability of UV LED curing to cure materials instantly not only speeds up production timelines but also improves product durability, making it a preferred choice among manufacturers.

Tips: When looking to adopt UV LED curing technology, consider the specific requirements of your production line. Evaluate the compatibility of UV LED systems with existing materials and processes to ensure seamless integration. Additionally, staying updated with the latest innovations can help you leverage competitive advantages in your industry.

The future of UV LED curing looks promising, with emerging trends pointing towards increased customization and automation. As manufacturers continue to seek ways to improve their processes, UV LED curing technologies are likely to adapt, incorporating smart features that allow for real-time monitoring and adjustments. This evolution signifies a shift towards a more interconnected manufacturing ecosystem where efficiency and precision are paramount.

The 2025 China Import and Export Fair is set to be a pivotal event for industry professionals, particularly in the realm of UV LED curing lamp innovations. As this sector continues to evolve, the fair presents a prime opportunity for networking, collaboration, and knowledge exchange among experts. Attendees will have the chance to engage directly with leading manufacturers, explore the latest technological advancements, and discuss trends shaping the future of the industry.

Tips for maximizing your networking experience at the event include preparing a concise elevator pitch that highlights your expertise and interests. This can open doors to meaningful conversations and potential partnerships. Additionally, consider scheduling meetings in advance with key industry leaders you wish to connect with. Having a targeted approach will help you make the most of your time at the fair and ensure valuable connections are established.

Lastly, don’t forget to leverage social media platforms to share insights and updates from the event. Engaging in real-time discussions can enhance visibility and create further networking opportunities. By being proactive and approachable, you can create lasting relationships that extend well beyond the fair.